Overview

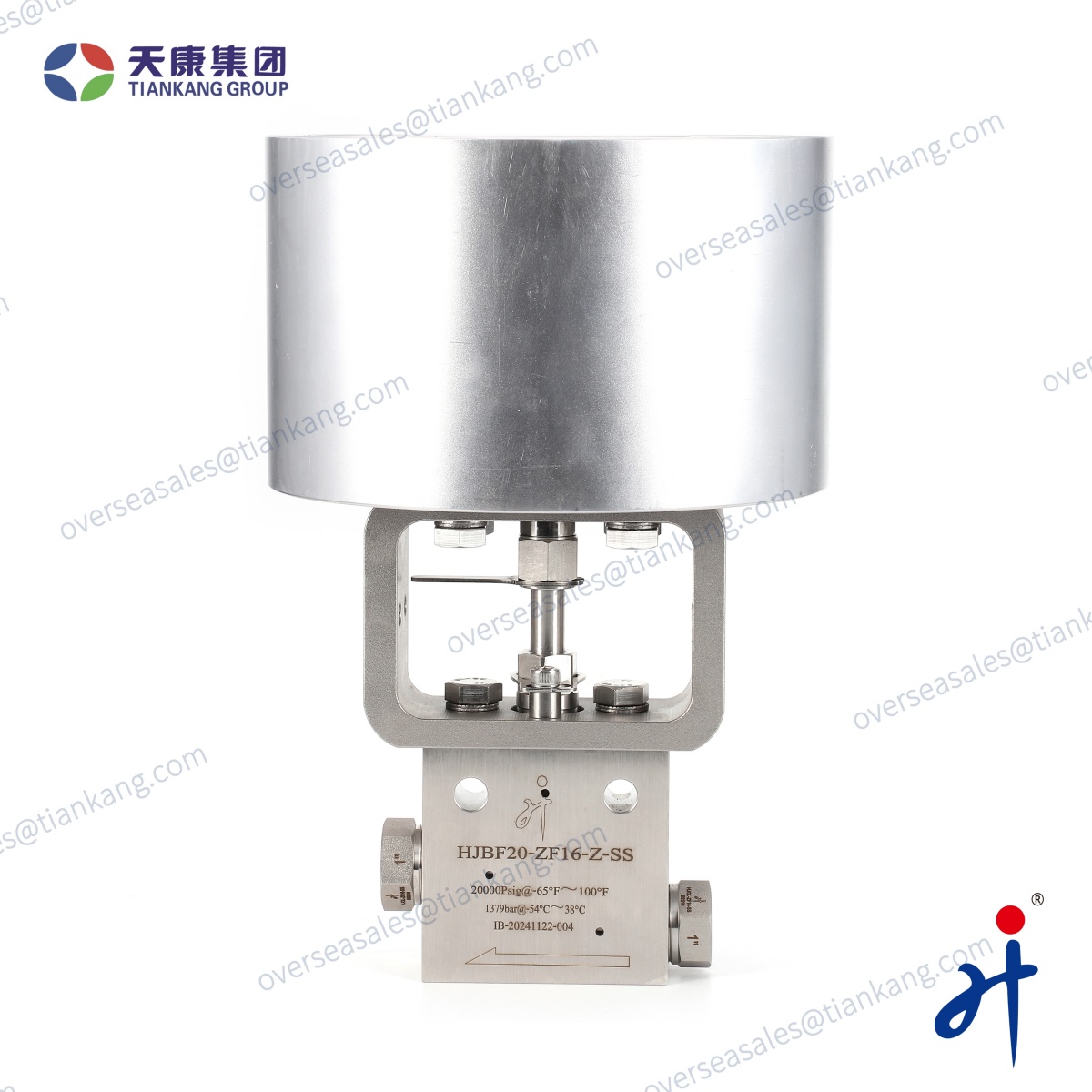

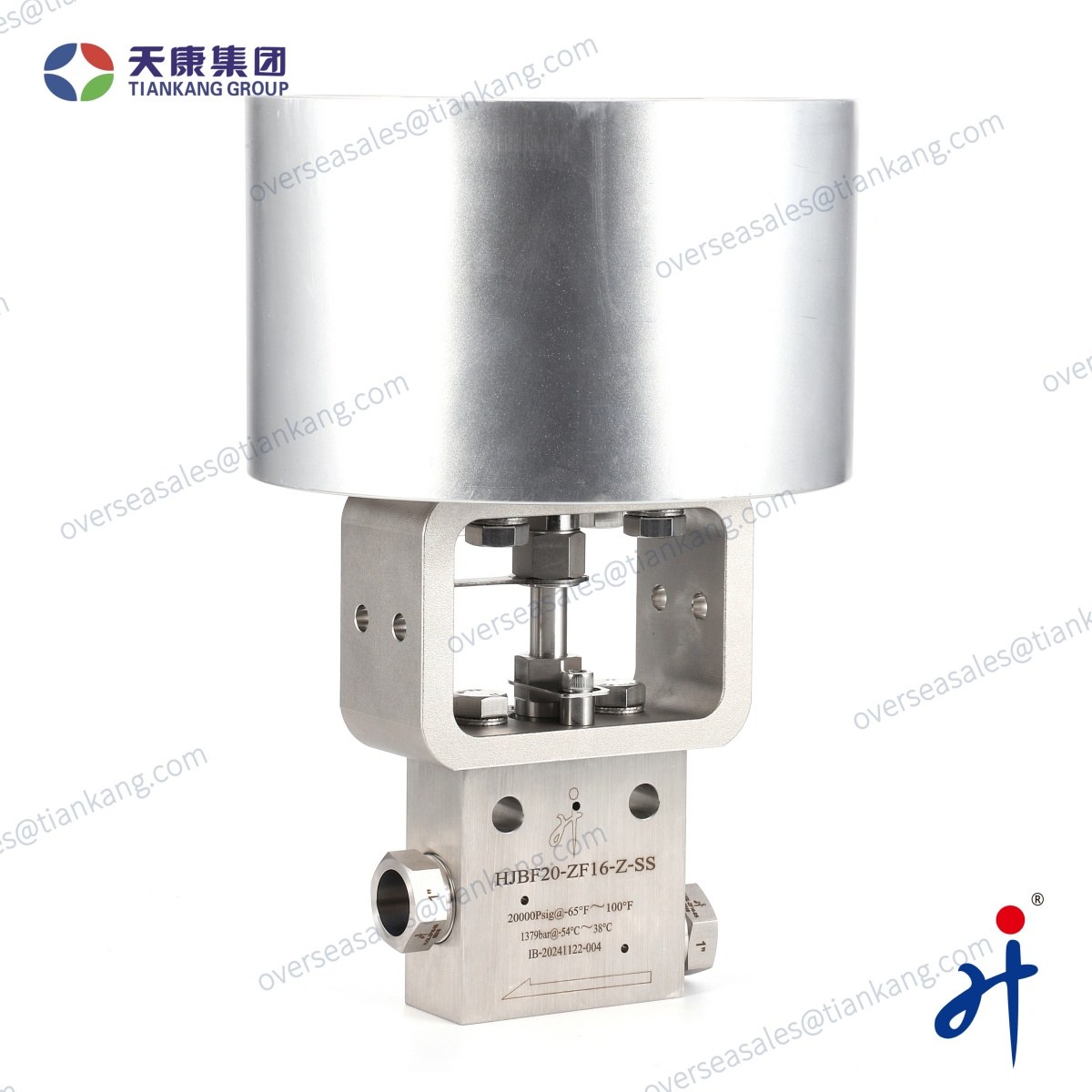

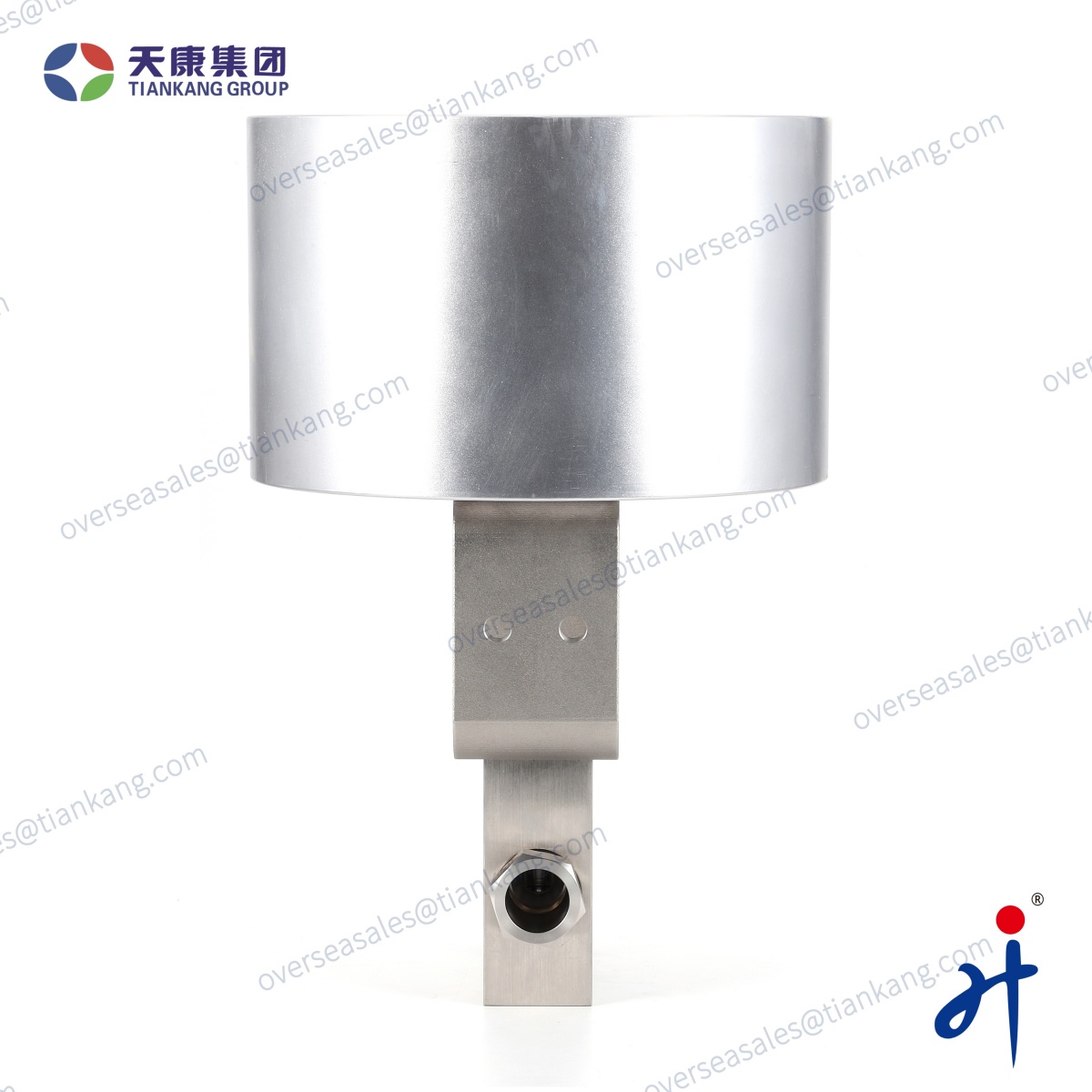

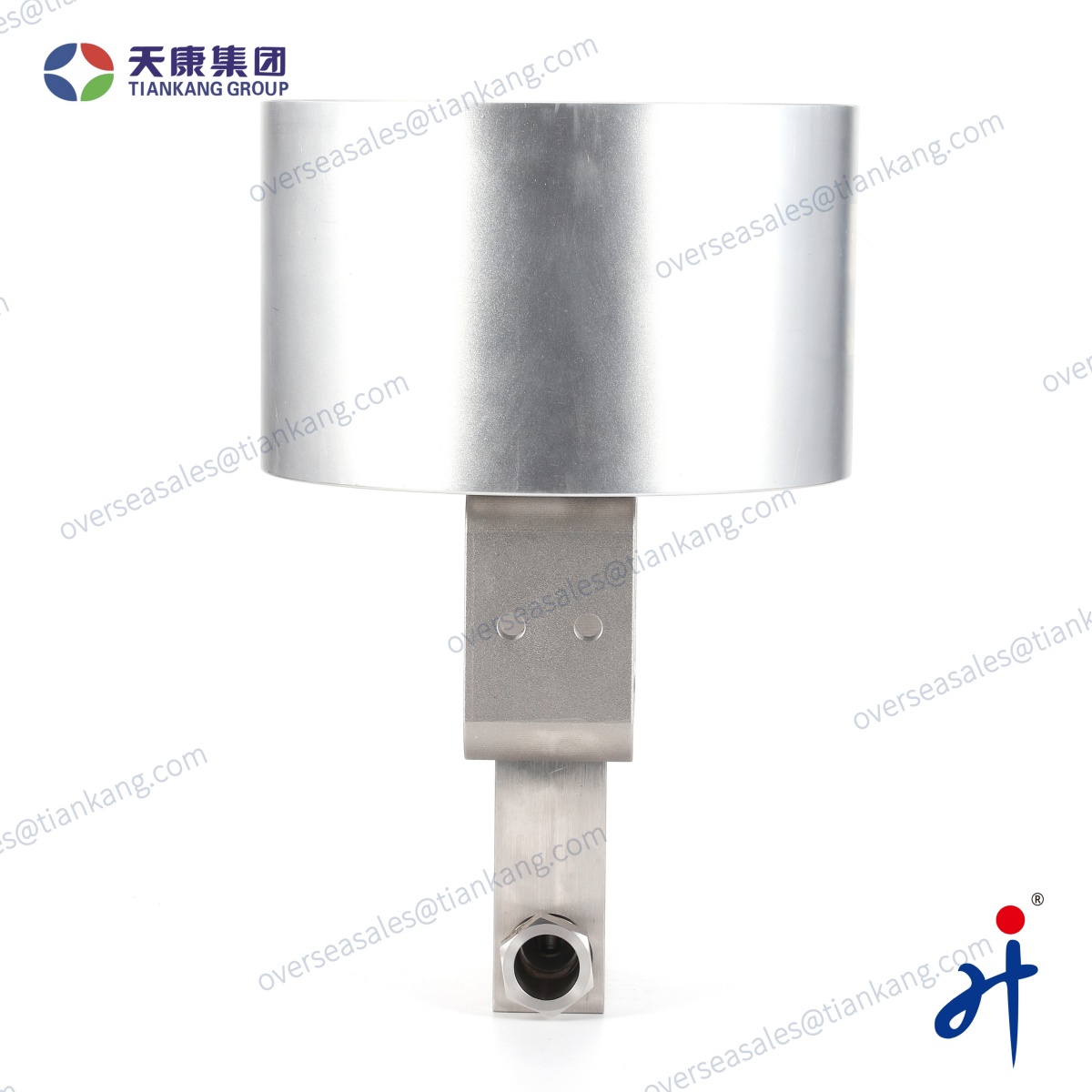

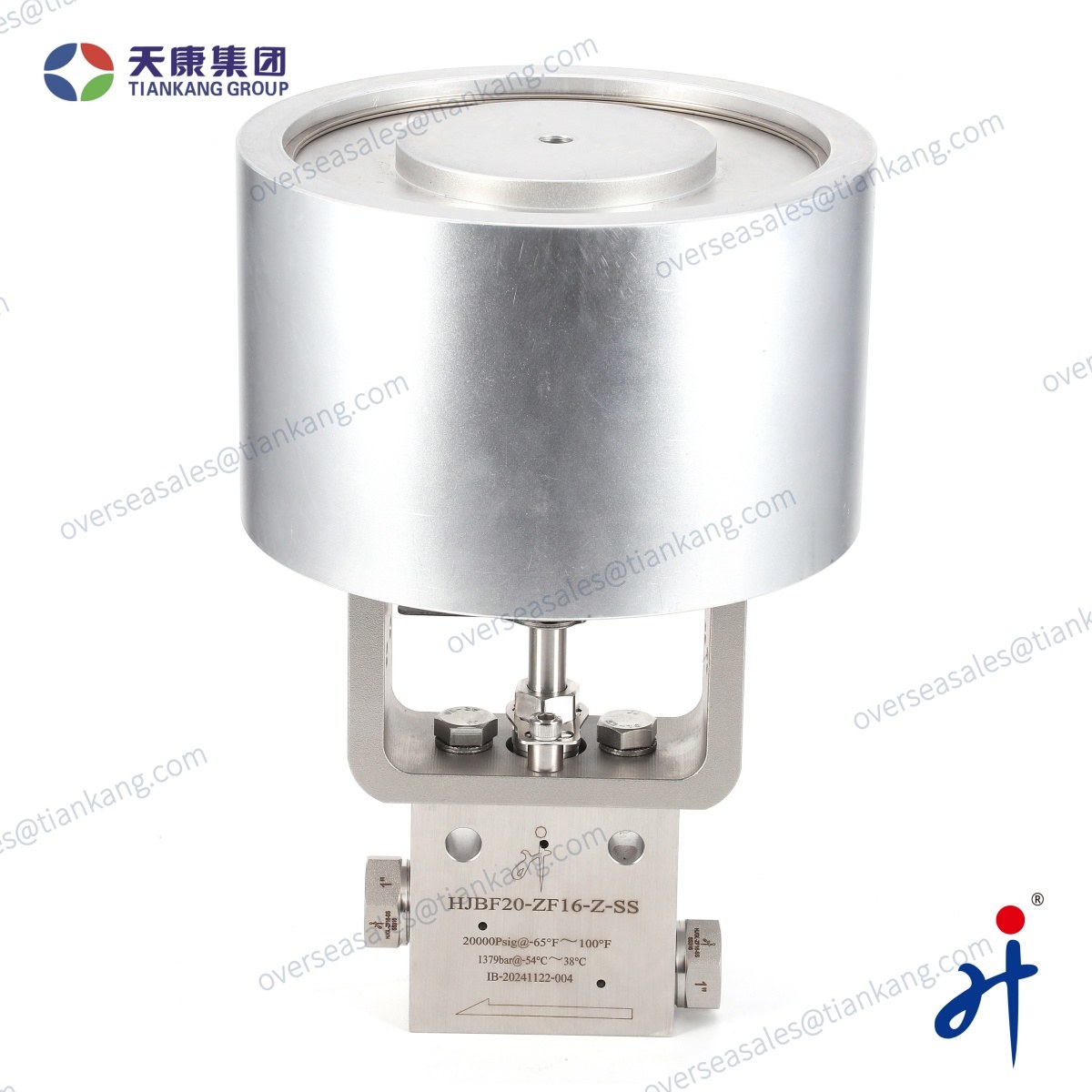

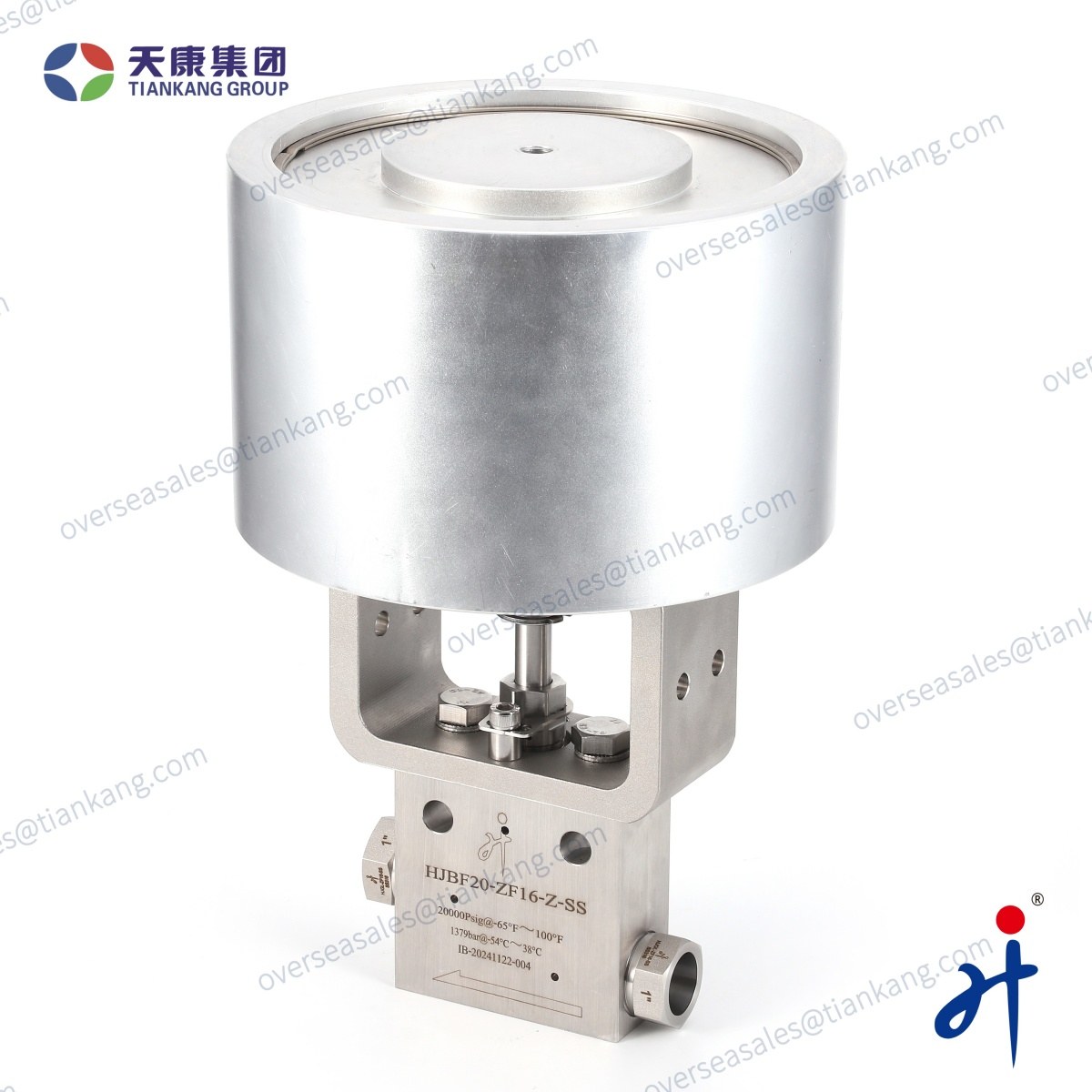

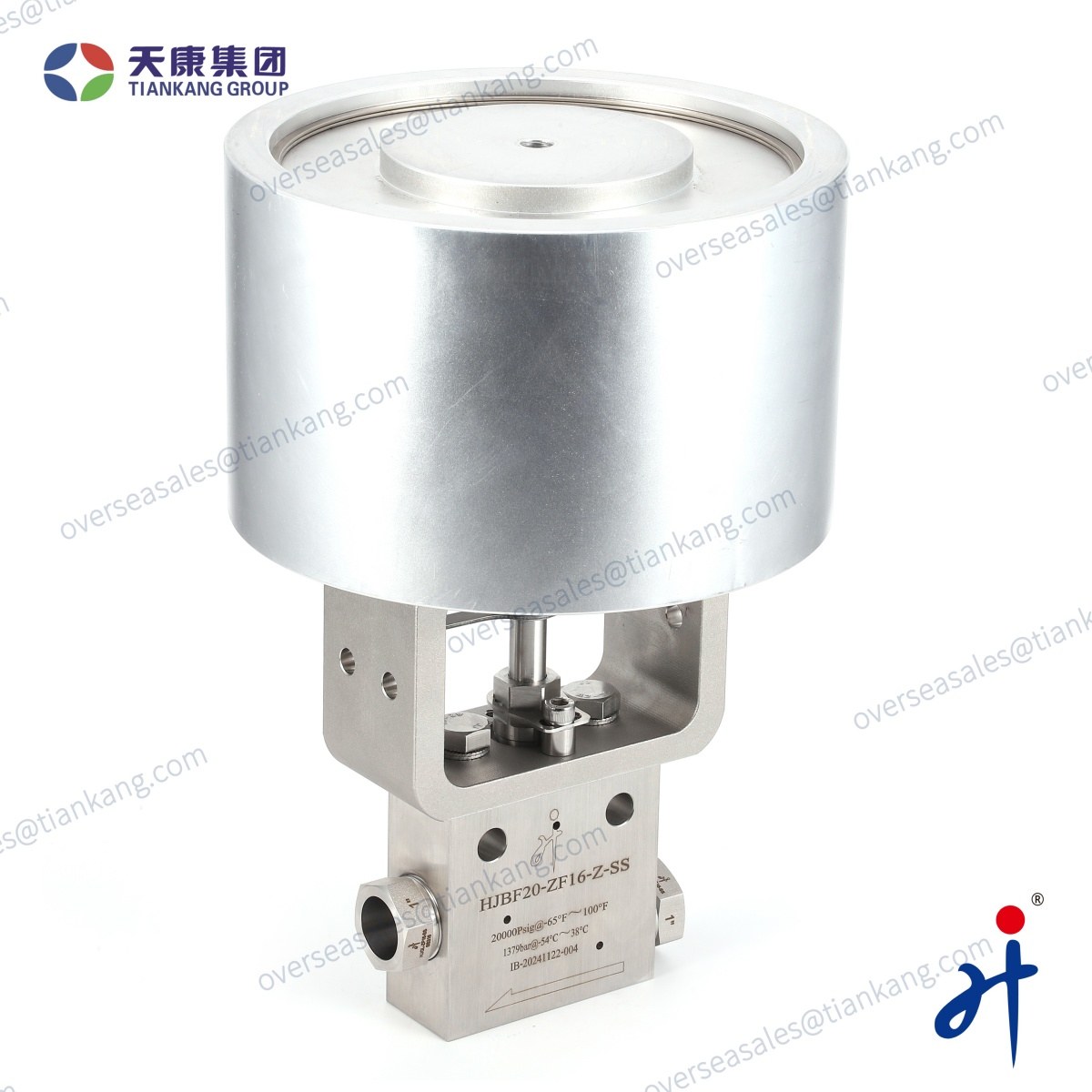

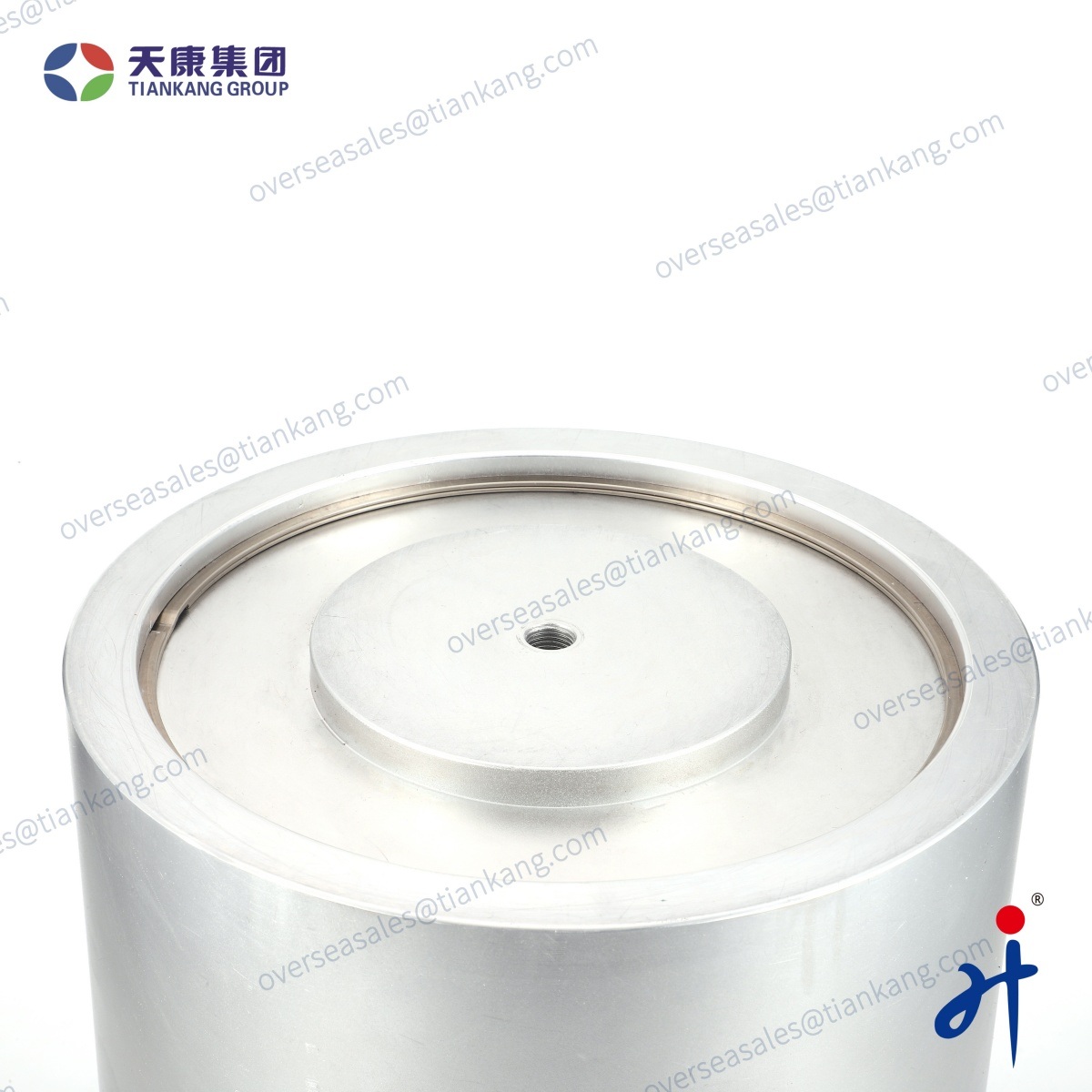

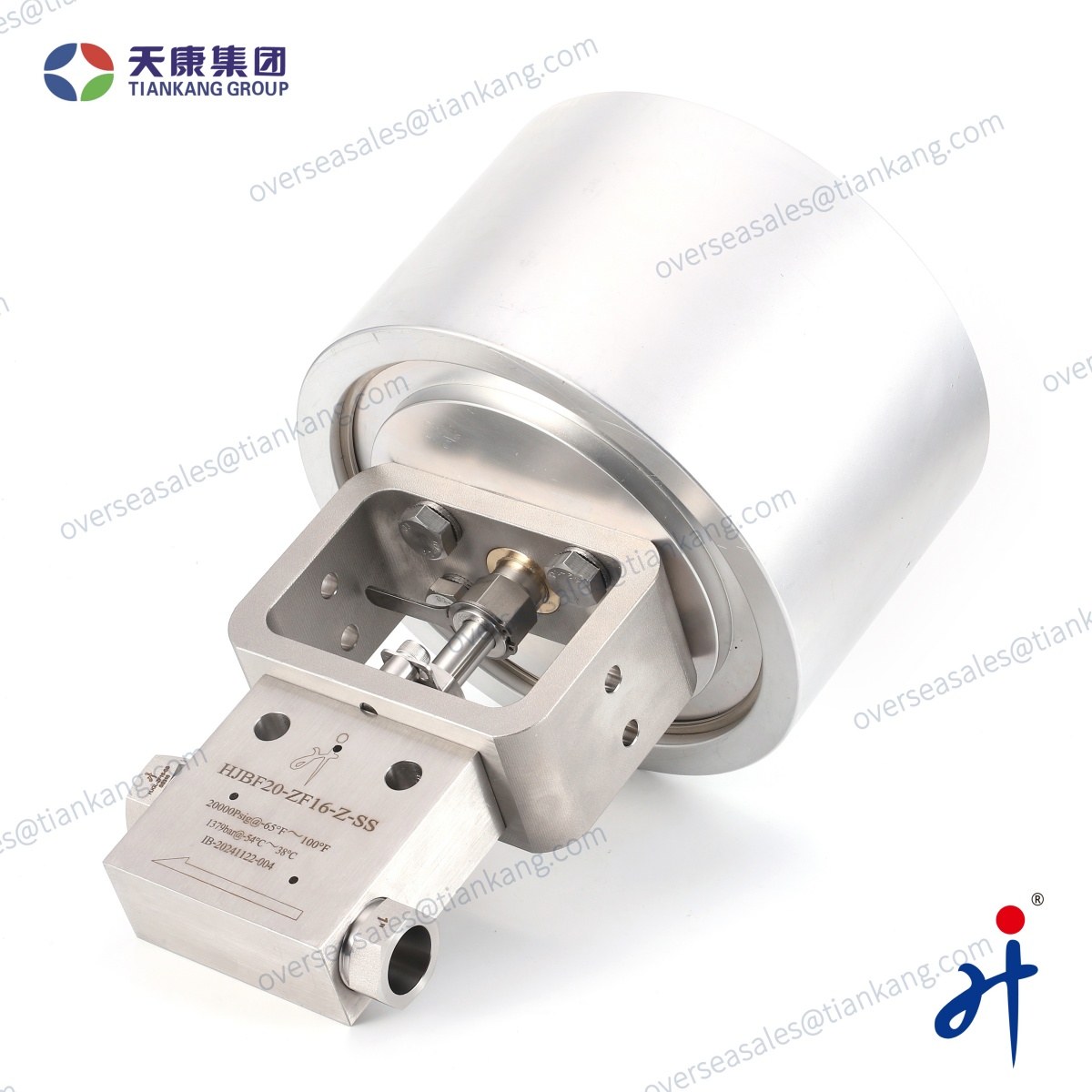

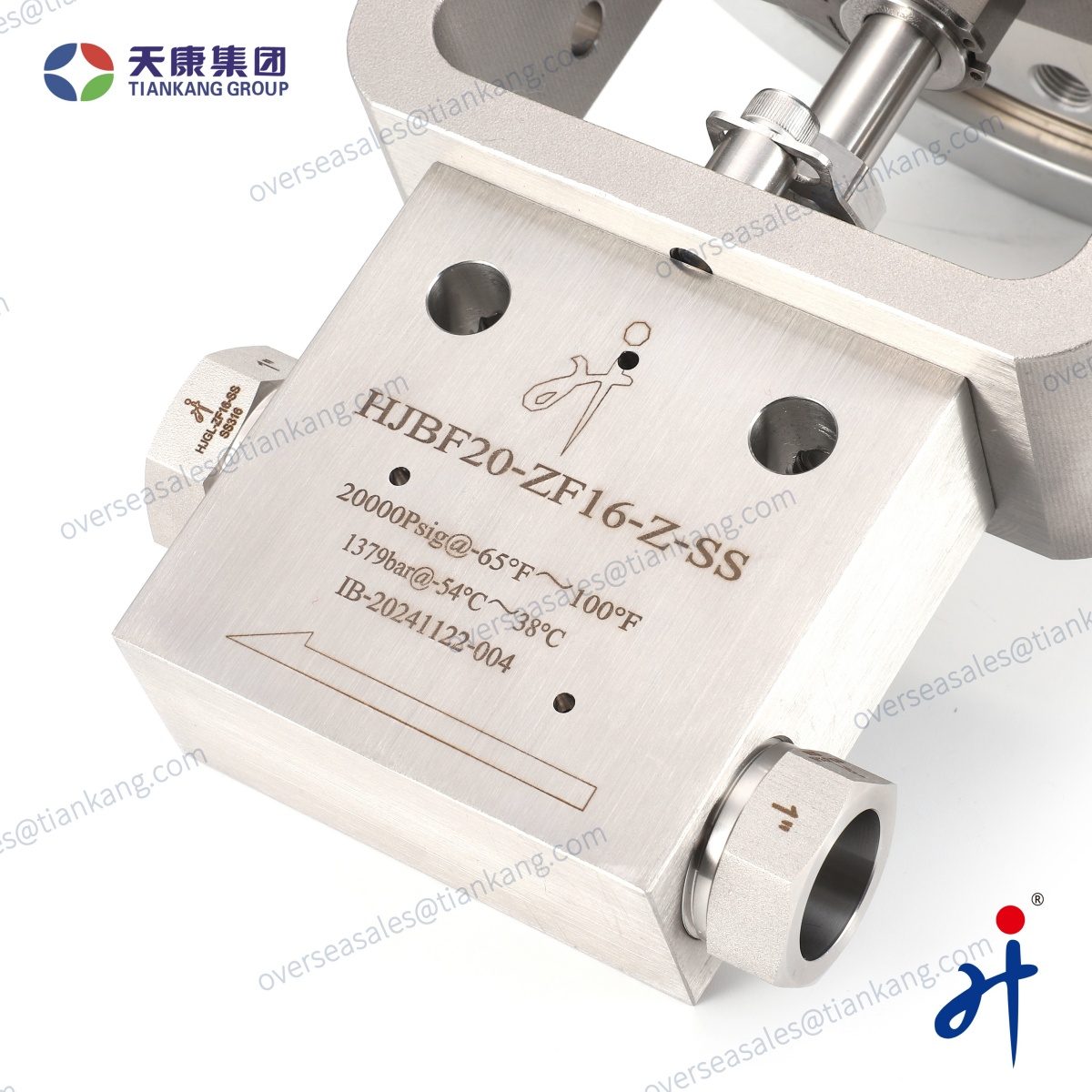

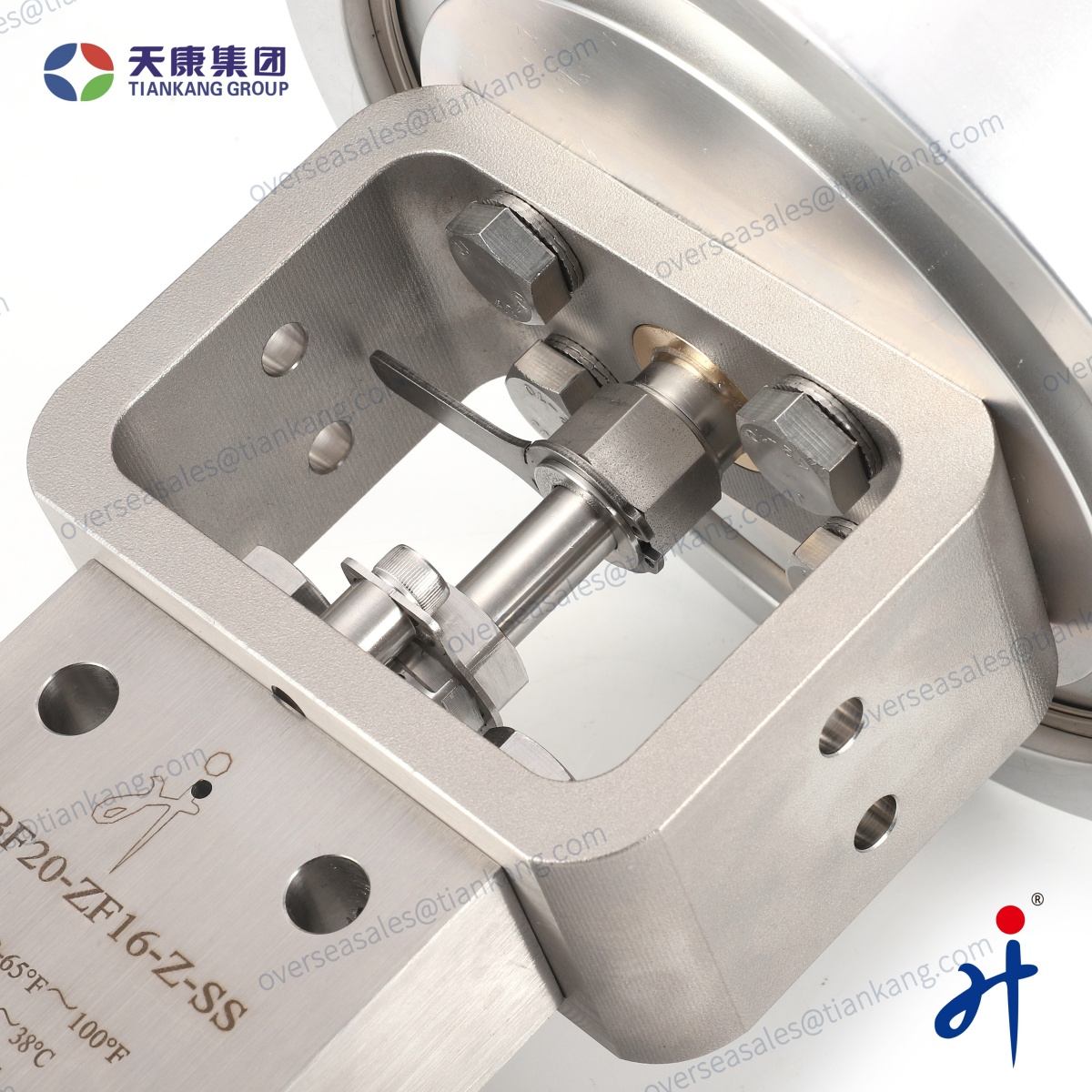

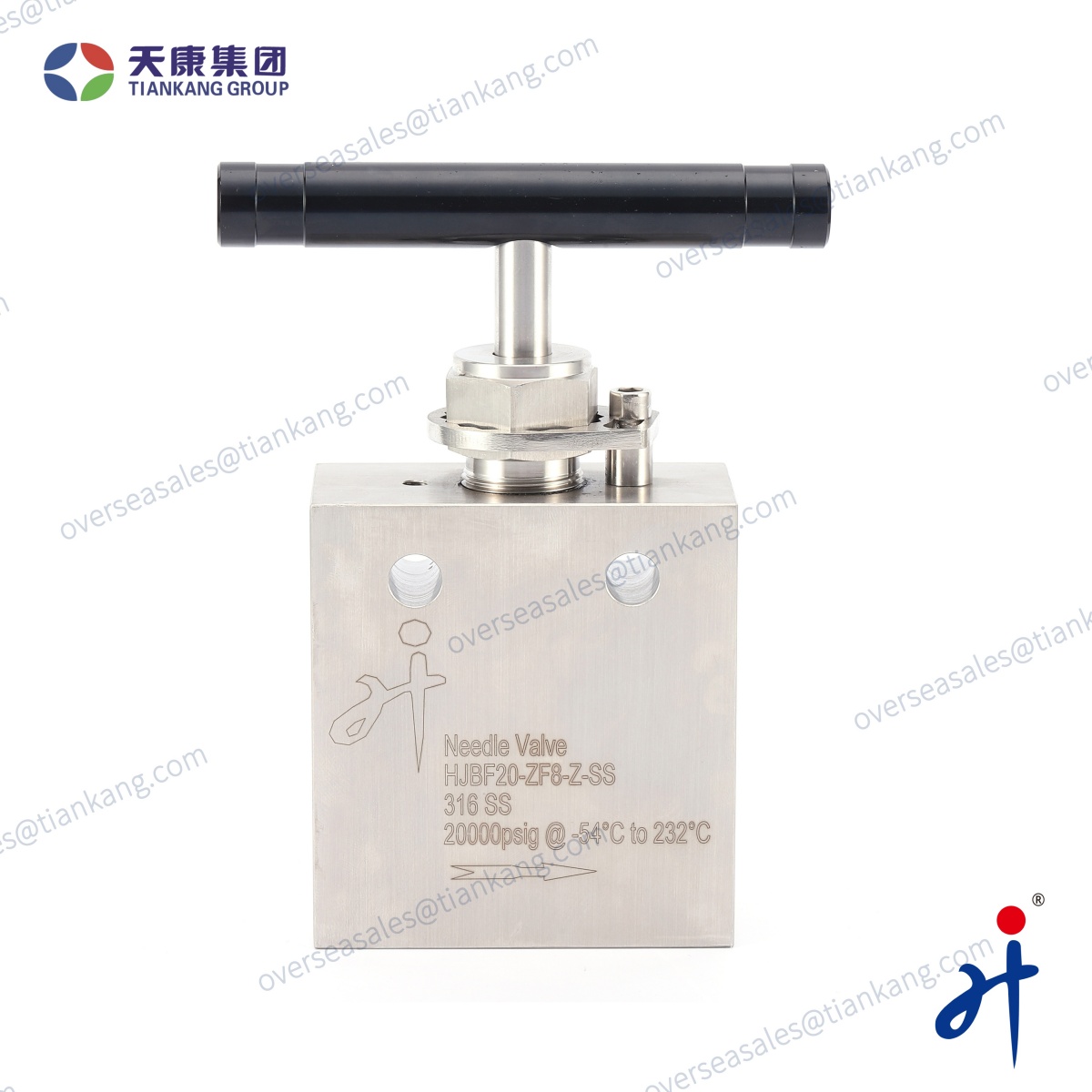

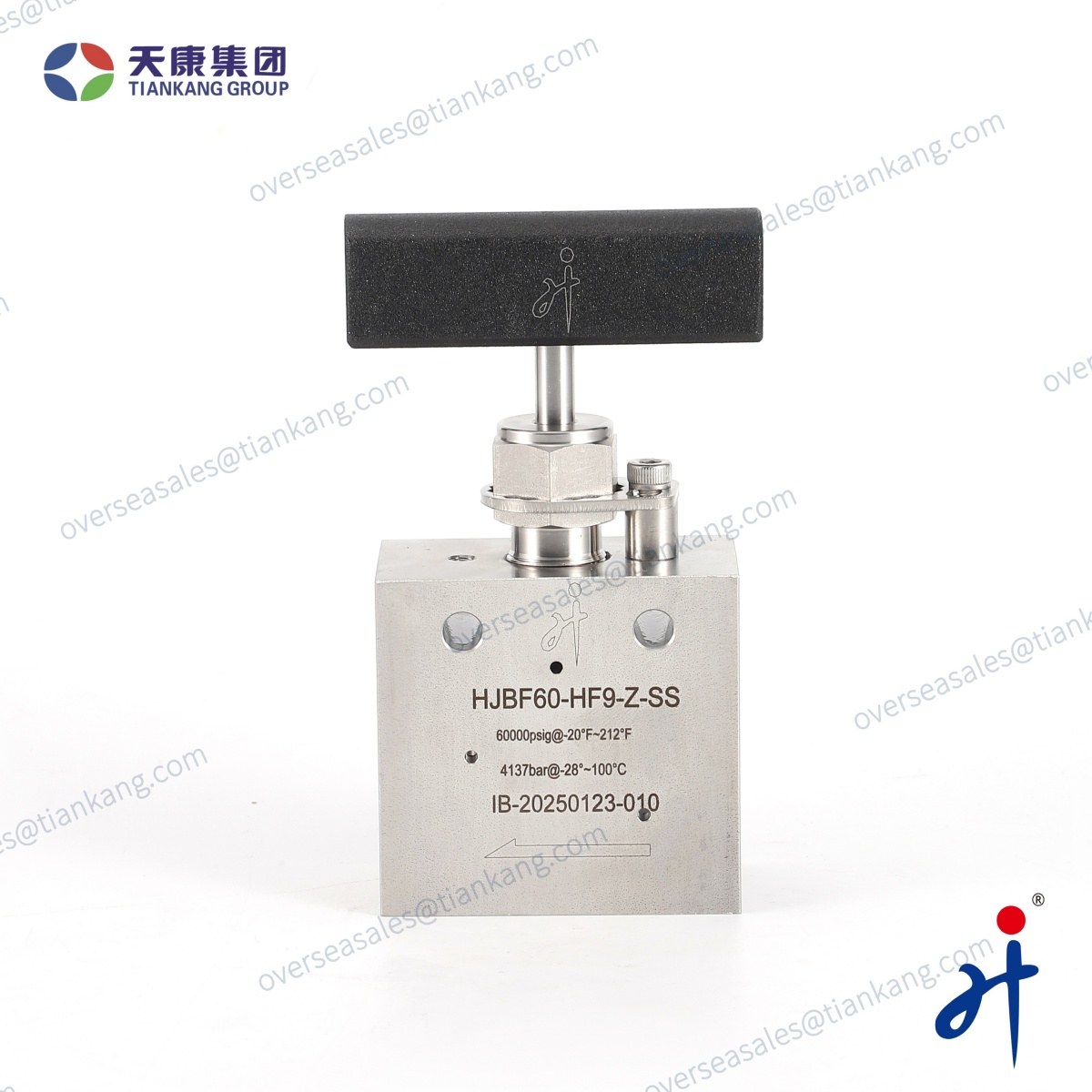

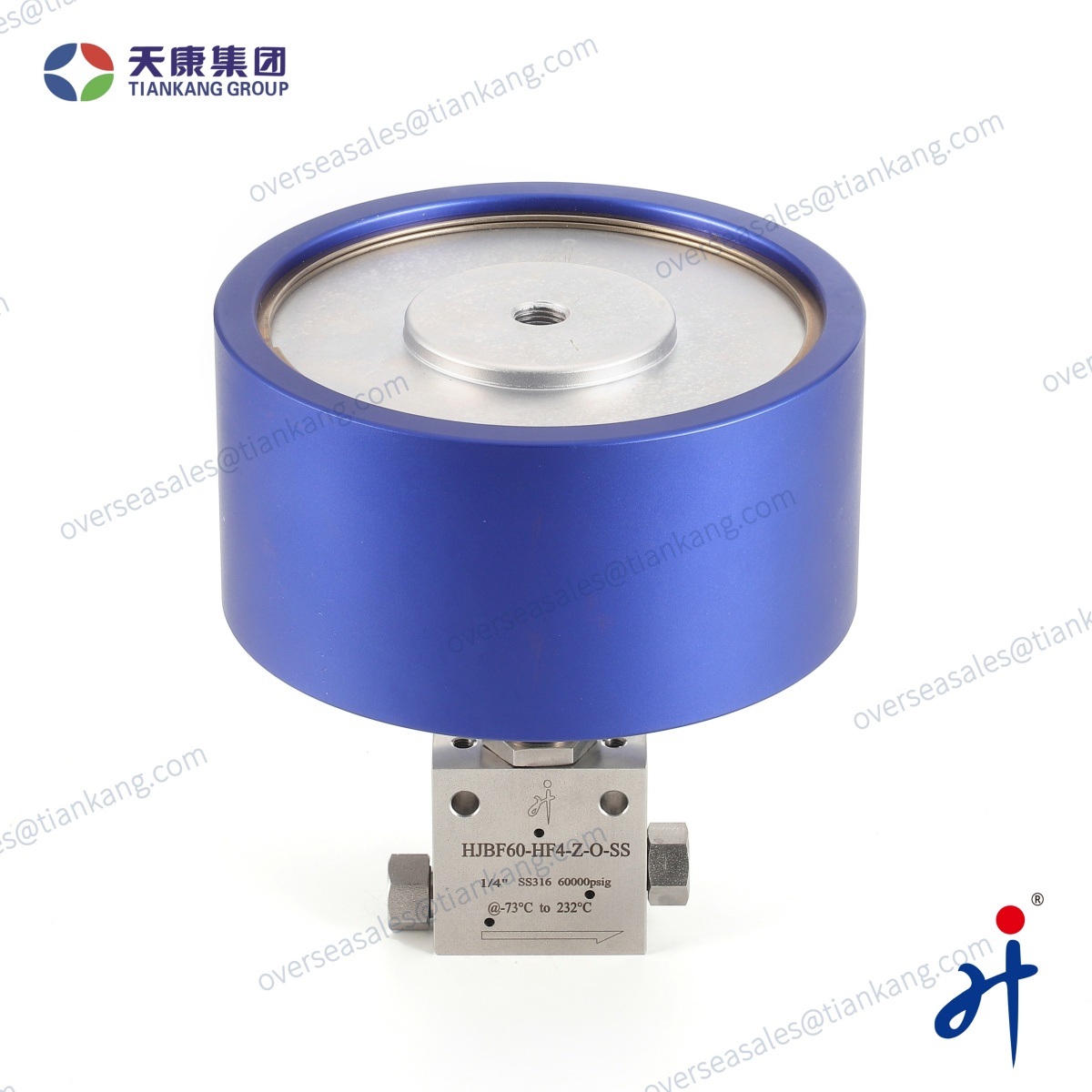

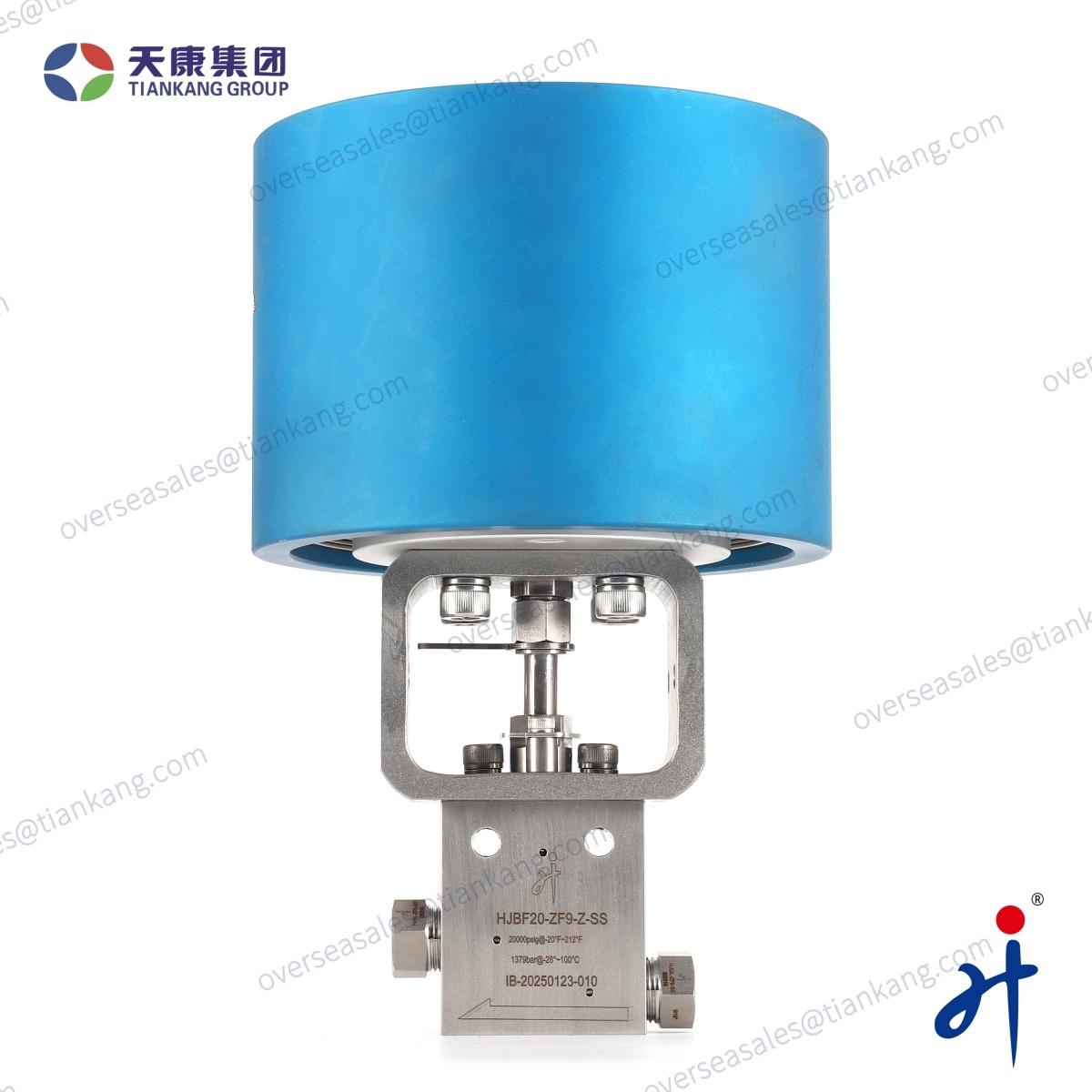

TianKang HongJi Ultra High Pressure Needle Valve with Actuator 20,000 psi 1" is a high-precision flow-control valve engineered for demanding systems operating at extremely high pressures, typically above 10,000 psi and up to 20,000 psi. Designed for accurate regulation of liquids and gases, this model is equipped with a compact small-cylinder pneumatic actuator, providing fast response, stable operation, and reliable remote control while significantly reducing manual handling under harsh conditions. The small-cylinder actuator delivers consistent needle positioning and excellent throttling accuracy even in fluctuating pressure environments. With its robust construction and high-pressure resistance, this valve is widely used in oil & gas testing, chemical process systems, aerospace hydraulics, and other applications requiring precise, safe, and efficient control of ultra-high-pressure media.

Technical Specifications

| Type |

Ultra High-Pressure Needle Valve |

Net Weight |

5.2kg(9/16") |

| Body Material |

SS316 |

Manufacturing Capacity |

800 pics/Month |

| Type of Connection |

Thread/Ferrule |

Warranty |

1 year |

| Seal Type |

Hard Sealing |

Manufacturing |

Forging and CNC |

| Packing |

PTFE/Graphite |

Pressure Range |

10,000Psi-60,000Psi (690Bar-1379Bar) |

| Media |

Liquid, Gas, Steam, Oil |

Size Range |

1/4" ~ 1" |

| Graphite |

-0°F to 800°F (-17.8℃ to 427℃) |

PTFE |

-100°F to 450°F (-73℃ to 232℃) |

Applications

- Oil & Gas: For controlling the flow of fluids in high-pressure pipelines.

- Chemical Processing: To regulate corrosive fluids in process lines.

- Aerospace: In high-pressure hydraulic systems.

- Manufacturing: For precise flow control in high-pressure machinery.

- Machine& Equipment: For pressurized sealing purposes.

- Laboratories and Research Facilities: Regulating sample flow in analytical instruments like gas chromatographs and mass spectrometers.

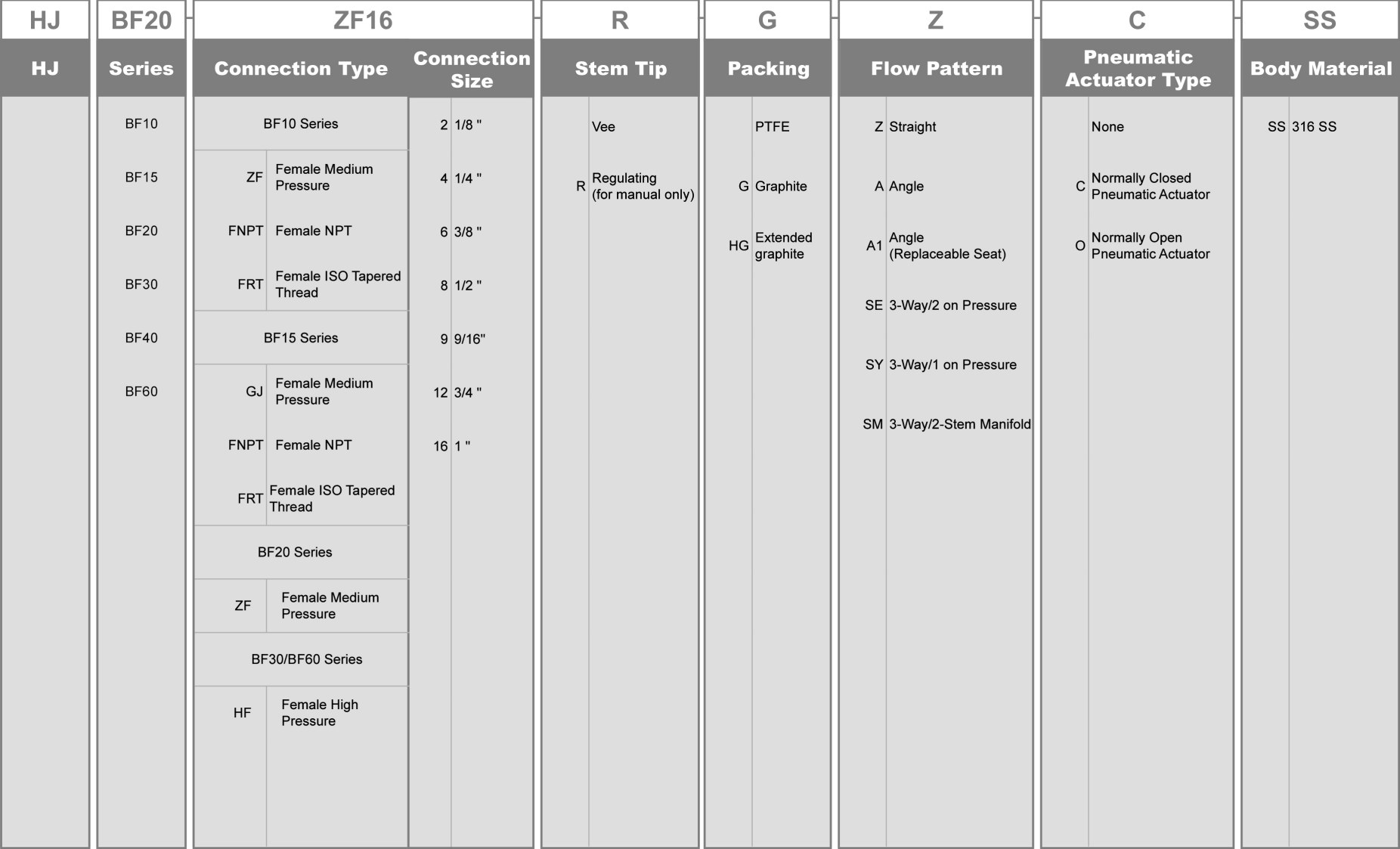

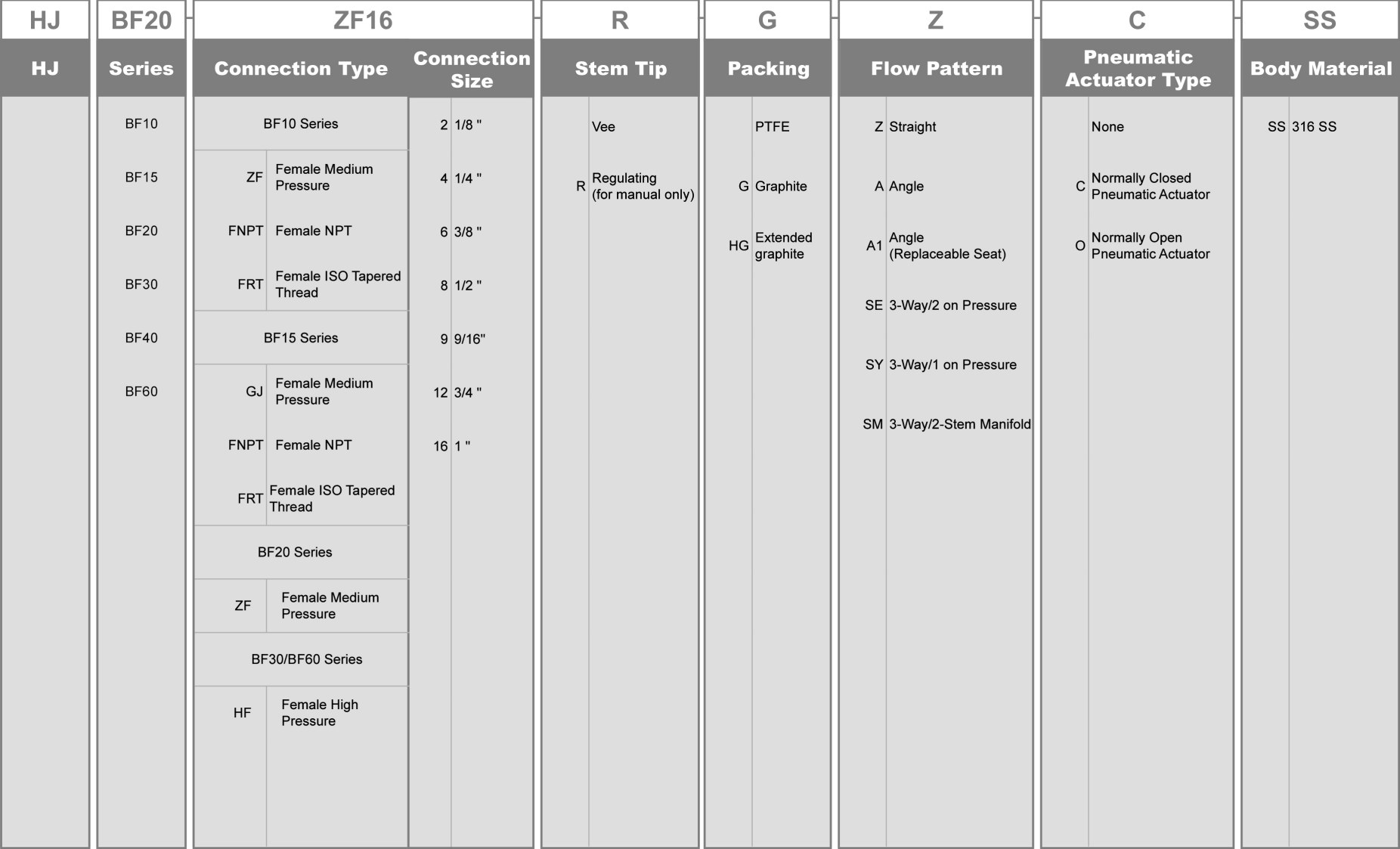

Ordering Number Description

Notes:

Packing may need to be adjusted during valve use.

For better maintenance, TianKang HongJi instrumentation needle valves should be stored in the half-open position.

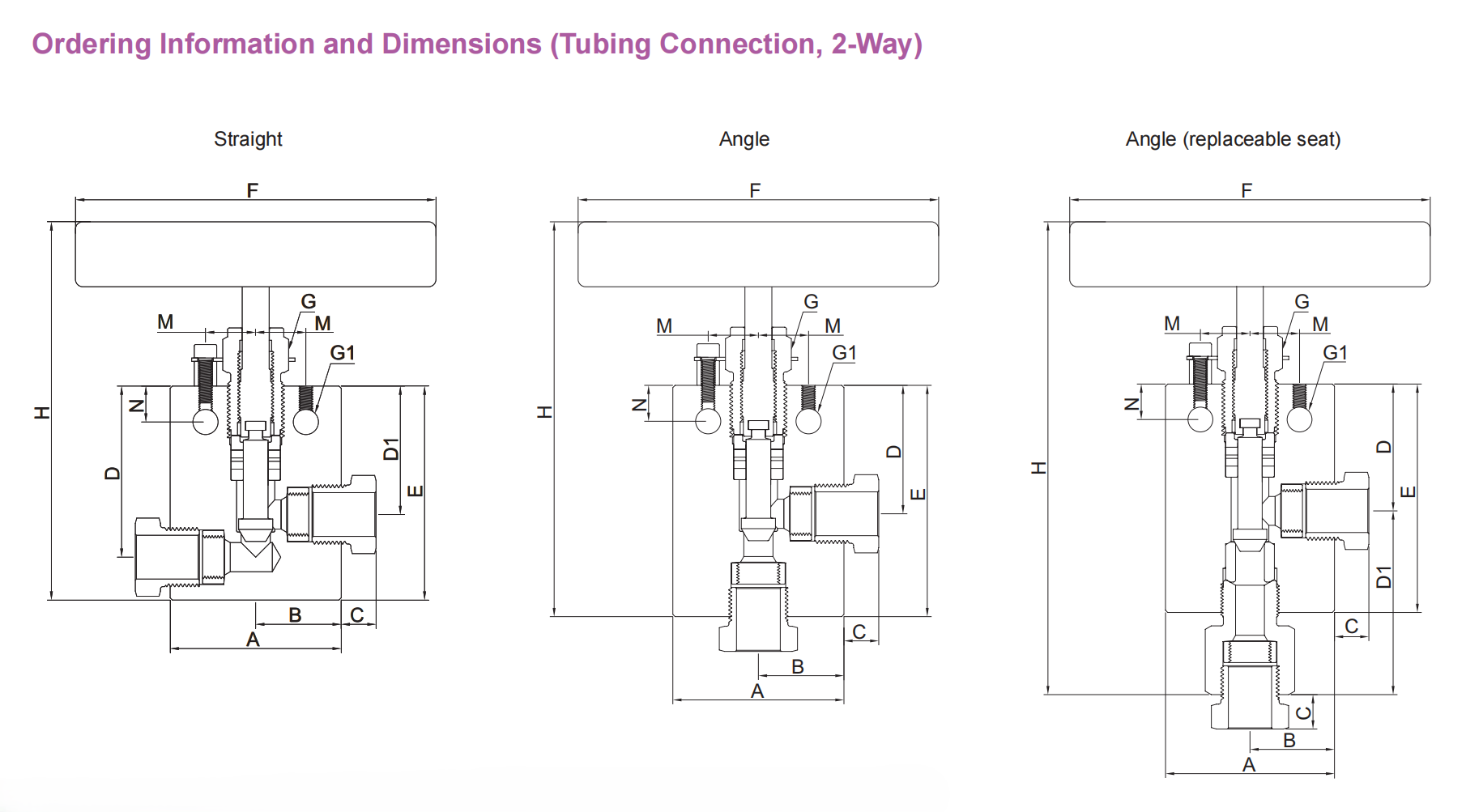

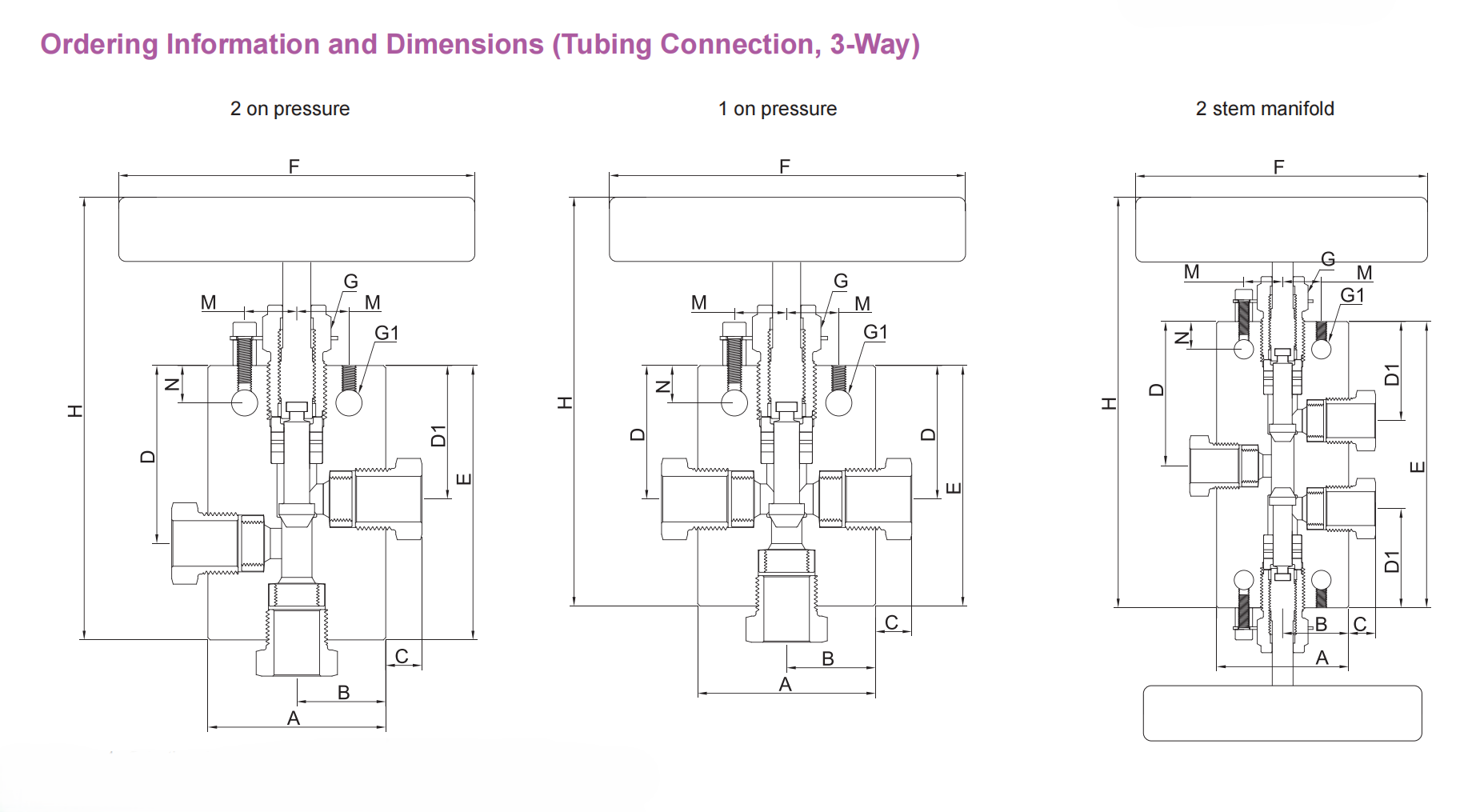

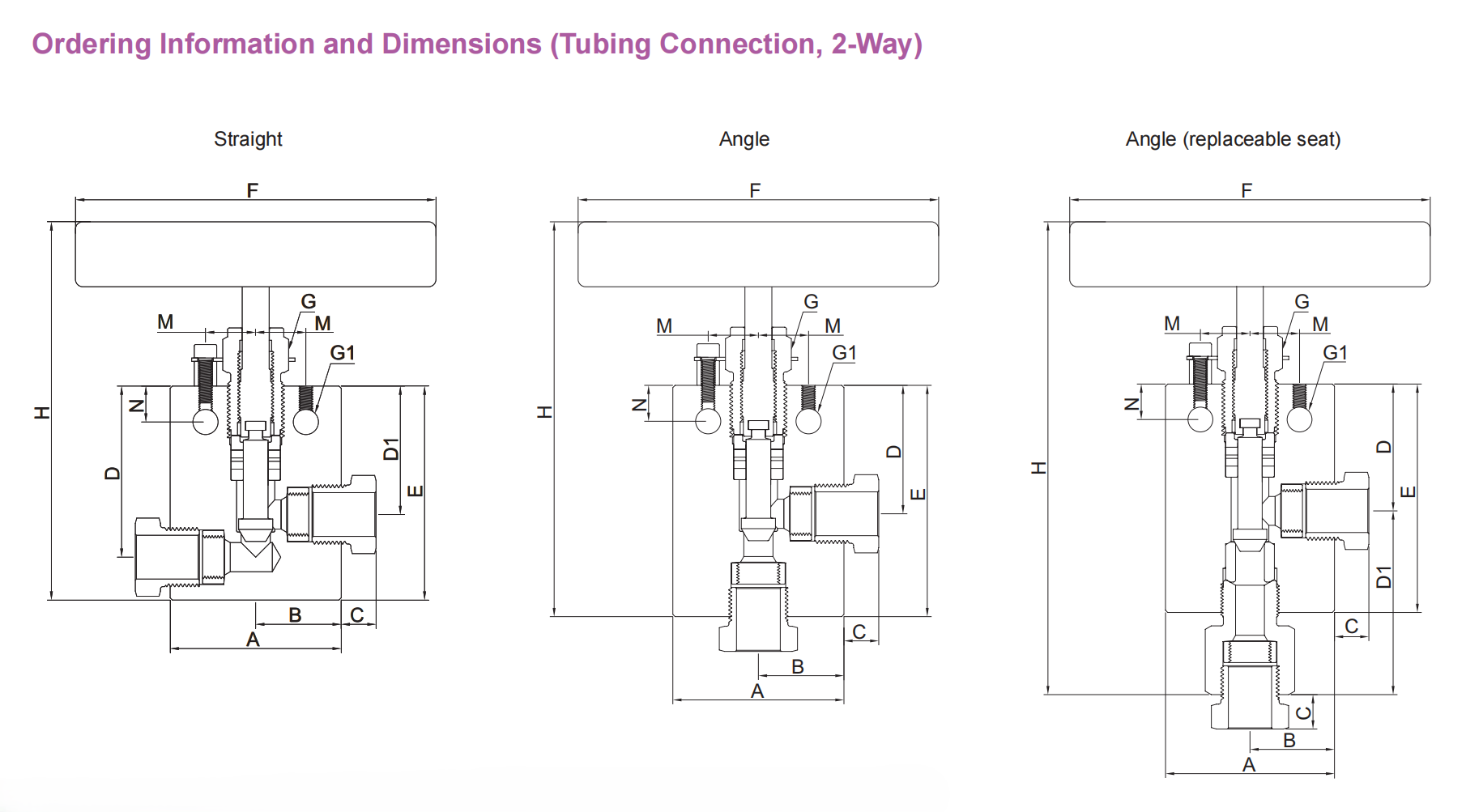

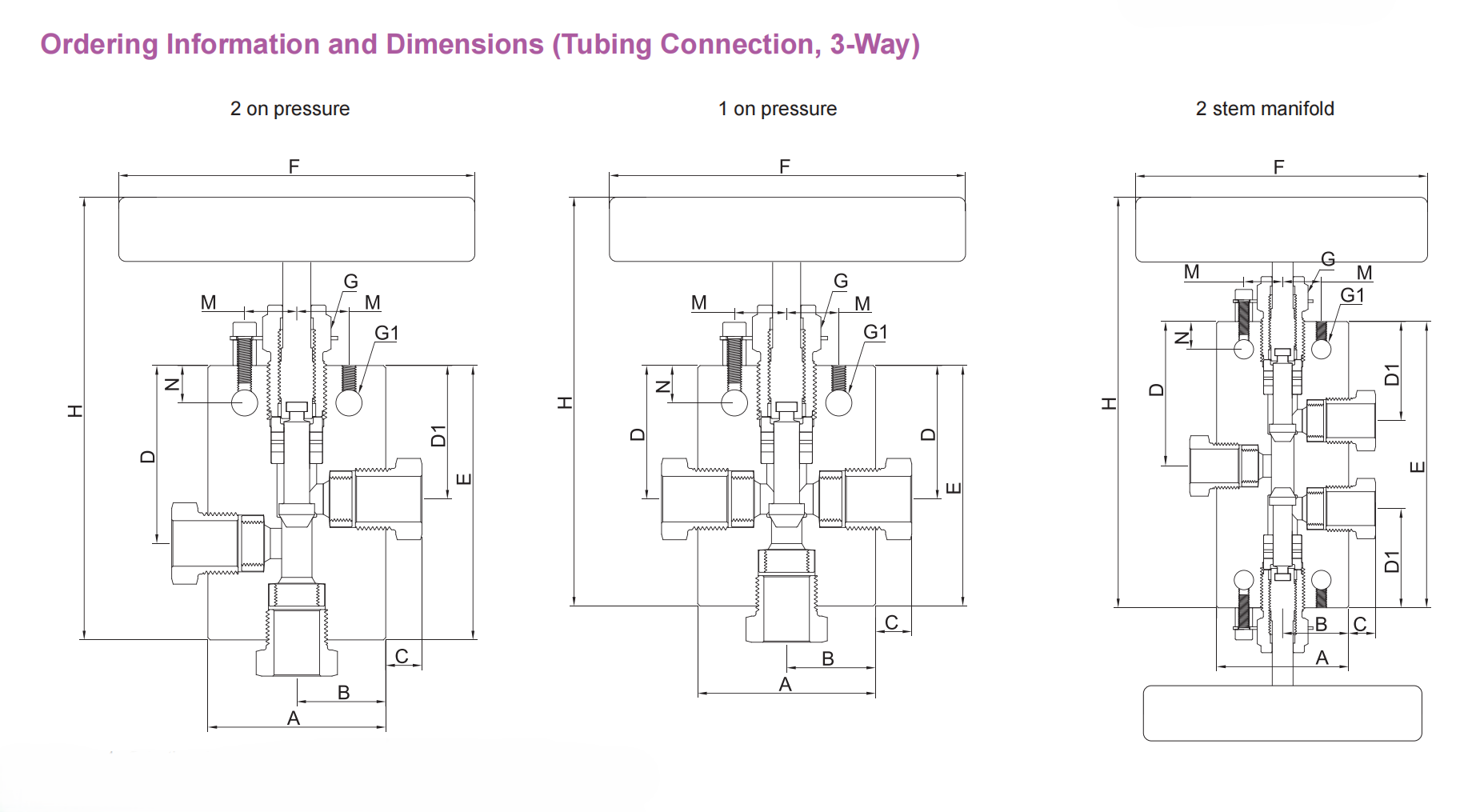

Ordering Information and Dimensions

Notes:

1.G is the drill dimension of packing gland mounting hole.

2.G1 is the dimension of bracket mounting hole.

3. Panel mounting drill size: 0.25" all valves

4. H is the dimension of stem in closed position.

5. Cy values provided are for the 2-way straight valve pattern, For the 2-way angle pattern, increase the Cy value by approximately 50% (based on water).

1/4" Female Medium Pressure Cv:0.31

3/8" Female Medium Pressure Cv:0.68

9/16" Female Medium Pressure Cv:1.30

3/4 " Female Medium Pressure Cv:2.50

1" Female Medium Pressure Cv.4.40

Customization & Technical Support

• E-Mail: overseasales@tiankang.com

Sales Support:

• E-Mail: sales06@tiankanginternational.com

English

English  Français

Français Русский

Русский Español

Español عربي

عربي

Network Supported

Network Supported