TianKang HongJi High Pressure Needle Valve 10000 psi is engineered for reliable and precise fluid control in extreme-pressure environments up to 10,000 psi (690 bar). Built with robust materials and a fine-threaded needle stem, it ensures accurate throttling, tight shutoff, and long-term stability in demanding applications. This high-performance needle valve is widely used in oil & gas transmission lines, chemical and petrochemical systems, hydraulic test equipment, aerospace assemblies, and other industrial processes requiring safe, precise, and leak-free regulation of liquids and gases. Its straight-through design delivers smooth flow characteristics, easy installation, and dependable performance even under continuous high-pressure operation—making it an ideal choice for critical instrumentation and control systems.

TianKang HongJi High Pressure Needle Valve 10000psi is a type of valves designed to control the flow of fluids (liquids or gases) in systems that operate at extremely high pressures-typically about 10,000 psi (690 bar) , depending on the design and materials. These High Pressure Needle Valve are commonly used in industries where precise flow control under high pressure is critical, such as oil and gas, chemical processing, aerospace, and other high-performance applications.

Technical Specifications

| Type | Ultra High-Pressure Needle Valve | Net Weight | 0.9kg(1/4") |

| Body Material | SS316 | Manufacturing Capacity | 800 pics/Month |

| Type of Connection | Thread/Ferrule | Warranty | 1 year |

| Seal Type | Hard Sealing | Manufacturing | Forging and CNC |

| Packing | PTFE/Graphite | Pressure Range | 6,000Psi-15,000Psi (414Bar-690Bar) |

| Media | Liquid, Gas, Steam, Oil | Size Range | 9/16" ~ 1" |

| Graphite | -0°F to 800°F (-17.8℃ to 427℃) | PTFE | -100°F to 450°F (-73℃ to 232℃) |

Applications

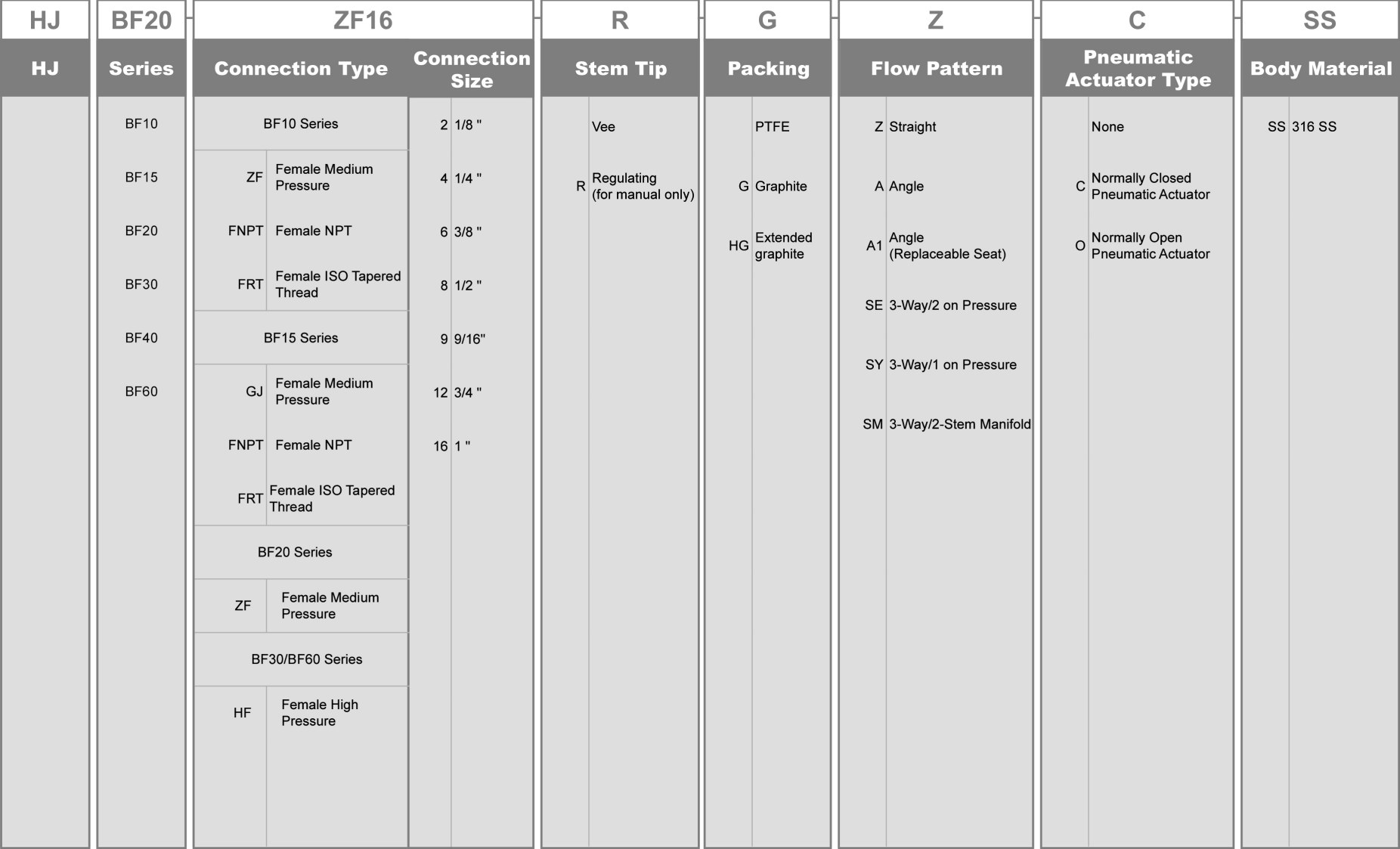

Ordering Number Description

Notes:

Packing may need to be adjusted during valve use.

For better maintenance, TianKang HongJi instrumentation needle valves should be stored in the half-open position.

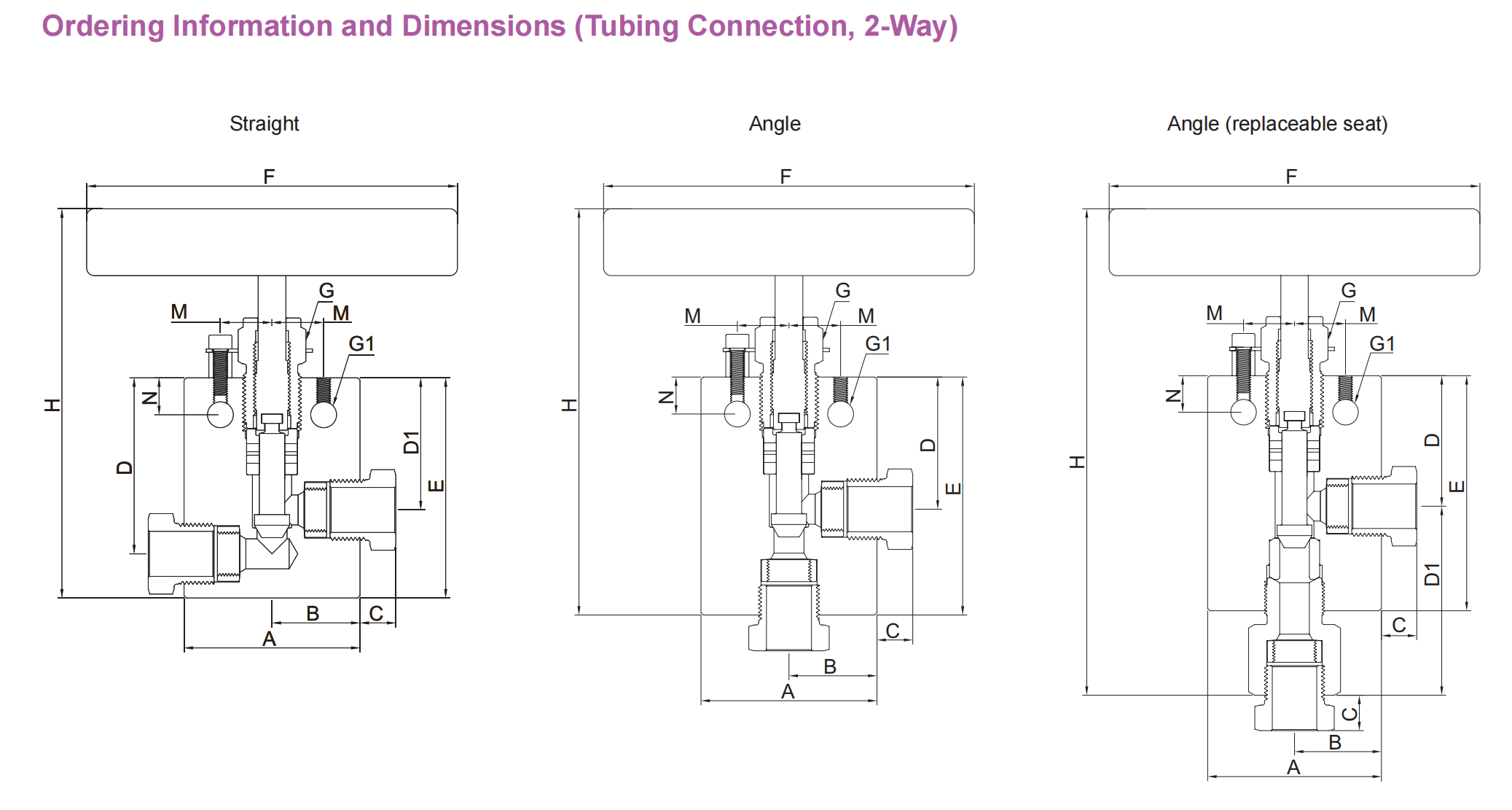

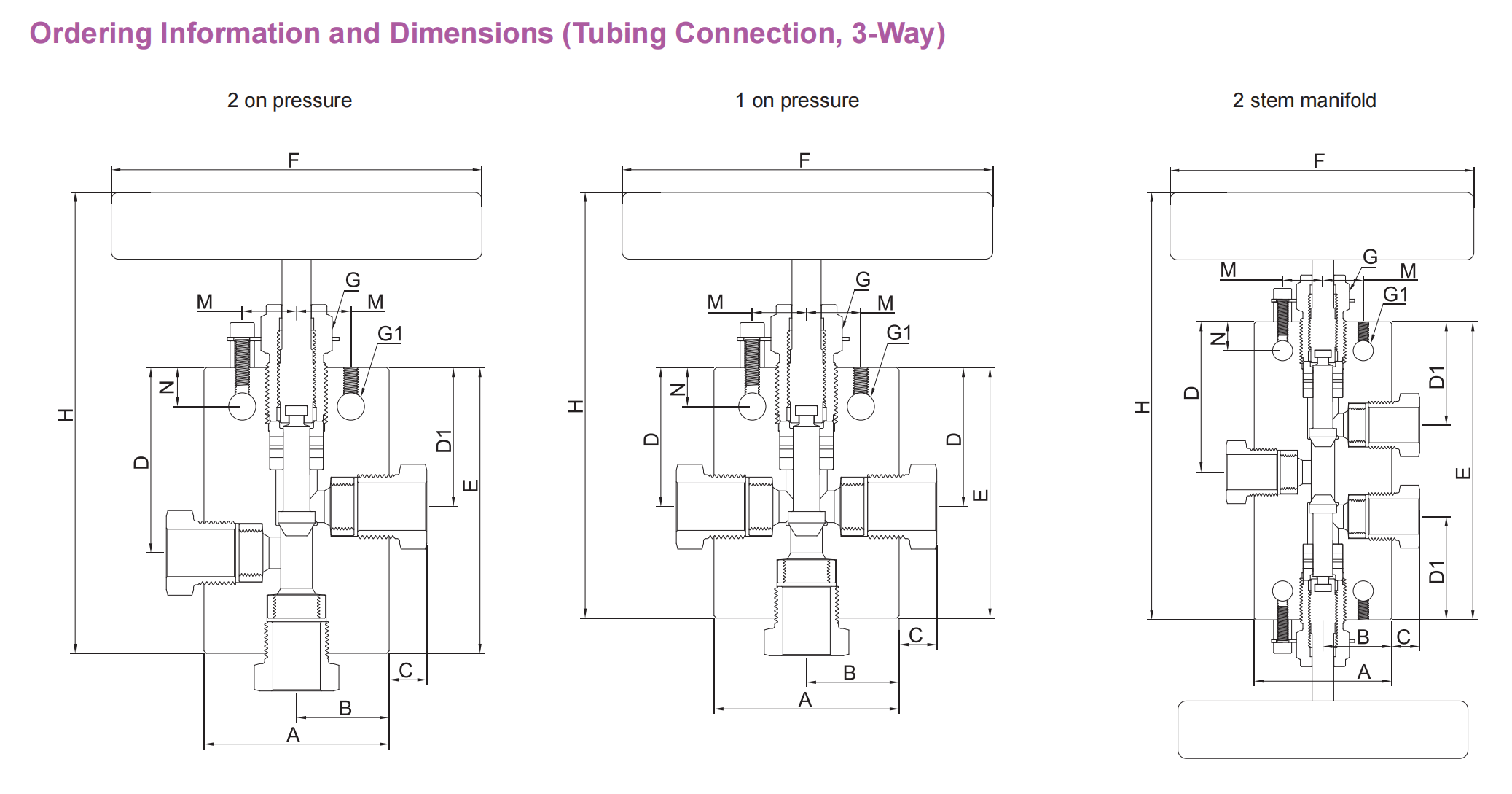

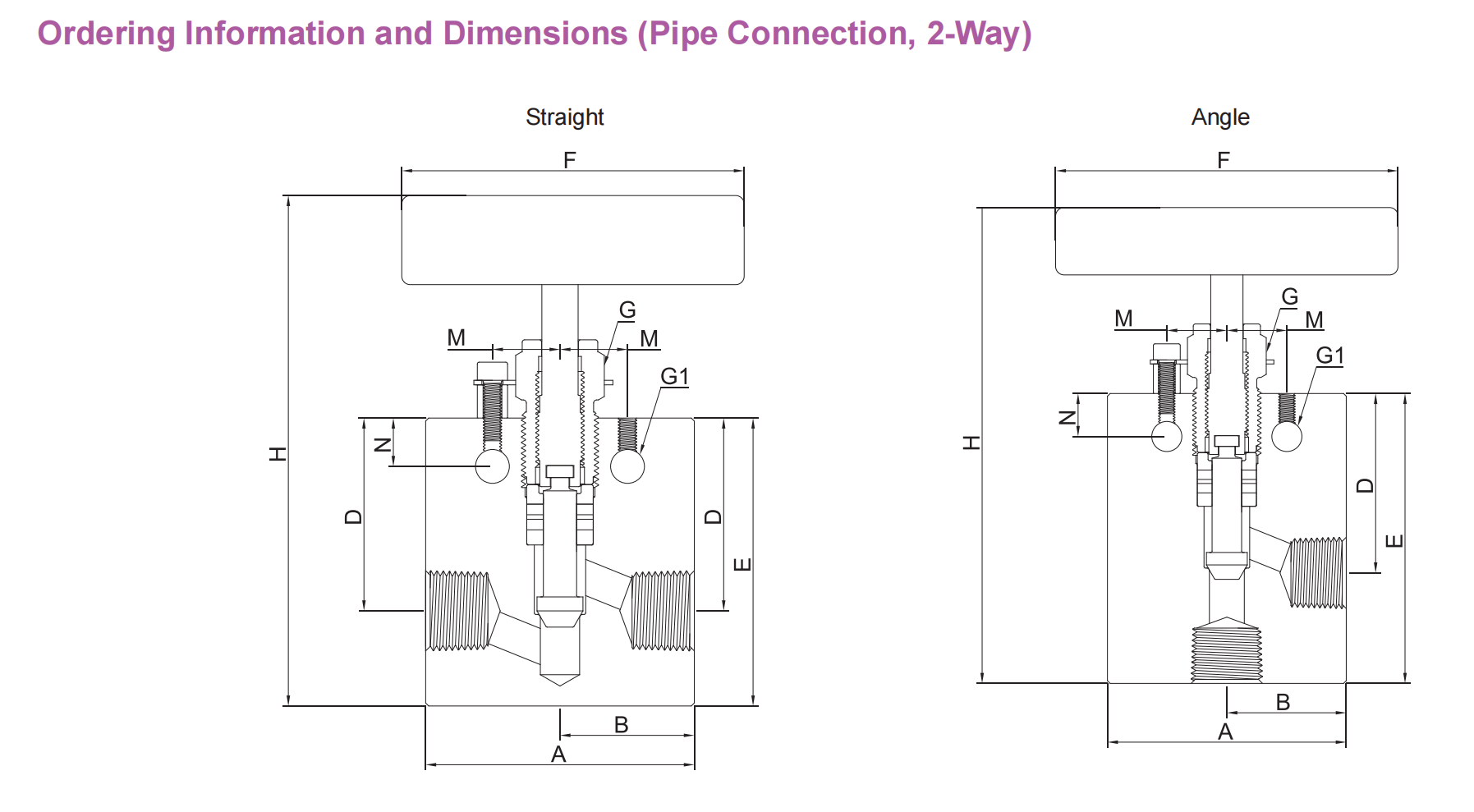

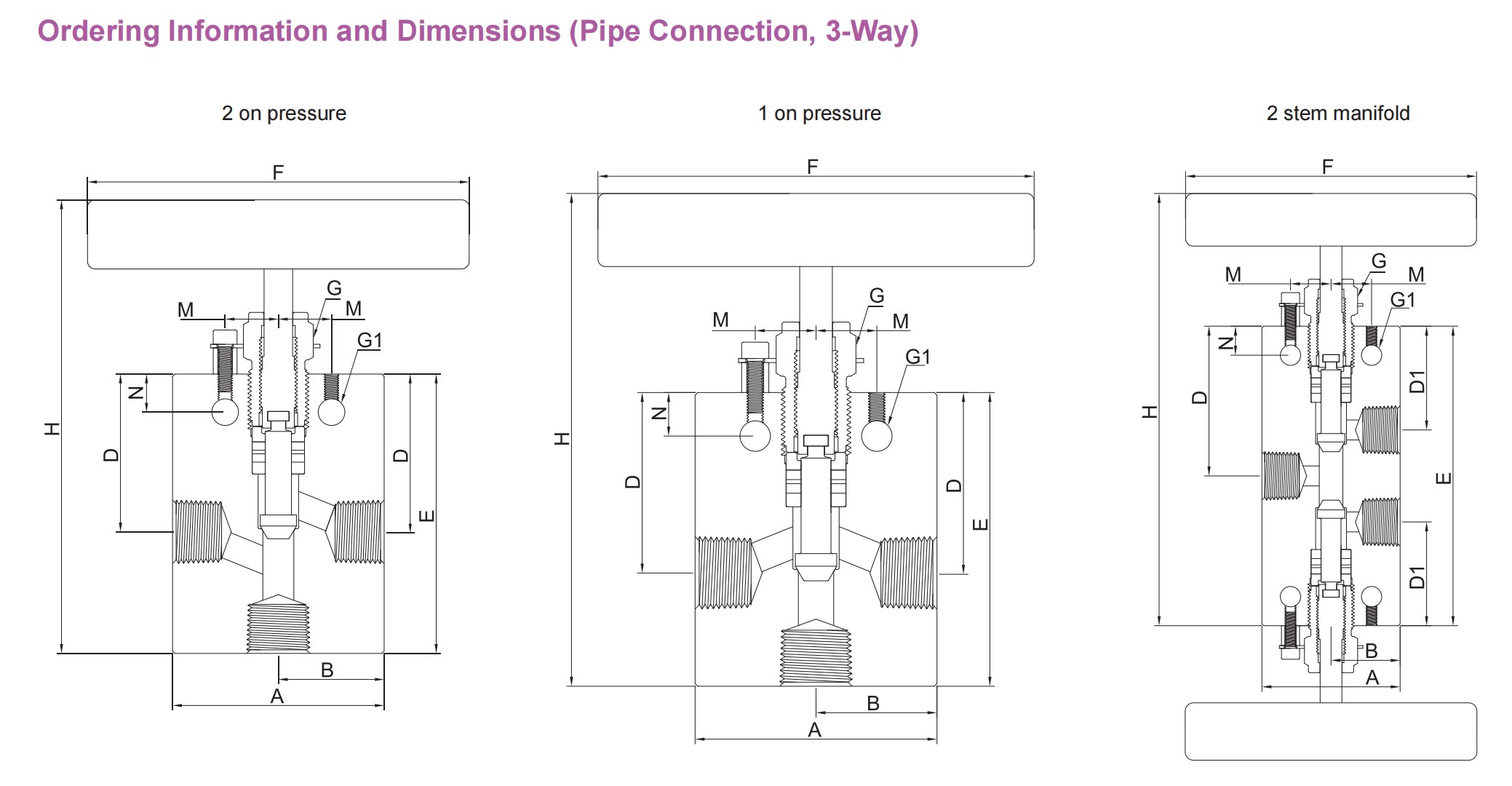

Ordering Information and Dimensions

Notes:

1. G is the drill dimension of packing gland mounting hole.

2. G1 is the dimension of bracket mounting hole.

3. Panel mounting drill size: 0.25" all valves.

4. H is the dimension of stem in closed position.

5. Cv values provided are for the 2-way straight valve pattern, For the 2-way angle pattern, increase the Cy value

by approximately 50% (based on water)

9/16" Female Medium Pressure Cv:1.75

3/4 " Female Medium Pressure Cv:2.80

1 " Female Medium Pressure Cv:5.20

3/4 " Female NPT & lSO Tapered Female Thread Cv:2.50

1 "Female NPT & lSO Tapered Female Thread Cv:4.40

Customization & Technical Support

• E-Mail: overseasales@tiankang.com

Sales Support:

• E-Mail: sales06@tiankanginternational.com

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2026 ANHUI TIANKANG (GROUP) SHARES CO.,LTD. All Rights Reserved. Network Supported

XML

Privacy Policy

Sitemap

Network Supported

XML

Privacy Policy

Sitemap

Email : overseasales@tiankang.com

Address : No.20 South Renhe Road,Tianchang,Anhui,P.R.C

Copyright @ 2026 ANHUI TIANKANG (GROUP) SHARES CO.,LTD. All Rights Reserved. Network Supported

Network Supported

Leave A Message