TianKang Mining Cables (English) TianKang mining cables serve underground coal and non-coal mines for power, control, and communication. They feature flame-retardant/fire-resistant performance, abrasion/oil/moisture resistance, high tensile and bending endurance, with options for rubber-sheathed flexible, trailing/reeling, shielded, and intrinsically safe designs. Compliant with or referenced to GB/T, MT, and IEC standards for safe and reliable operation in harsh environments.

Overview

Mining cables are engineered for underground coal and non-coal mines, tunnels, and surface mining operations, providing power, control, and communications under harsh, mechanically demanding, and safety-critical conditions. Common constructions include rubber‑sheathed flexible cables for mobile equipment, trailing/reeling heavy‑duty cables for shearers, loaders, and shuttle cars, and shielded intrinsically safe cables for control and monitoring. Designs emphasize flame resistance, low smoke/halogen options, oil/abrasion resistance, and high flexibility with tight bending radii.

Typical voltage ratings (power): 0.66/1.14 kV, 1.9/3.3 kV, 3.6/6 kV, 6/10 kV, 8.7/15 kV

Conductors: Copper, flexible Class 5/6, tinned optional for corrosion resistance

Insulation: EPR or XLPE; rubber compounds for flexible types

Shielding: Individual/overall screens for control and IS circuits; copper braid/tape optional

Mechanical protection: Textile braid, anti-tear separators, optional armor for specific surface applications

Outer sheath: Heavy‑duty rubber (chloroprene, CPE, TPU options), LSZH rubber for fire‑critical zones

Applications: Underground headings, longwall faces, mobile machinery trailing, reeling systems, pump and fan feeds, conveyor systems, control/monitoring, intrinsically safe circuits

Standards: MT (China mining standards), GB/T relevant mining cable specs, IEC 60228 (conductors), IEC/EN 50525 (as applicable), IEC 60332/60754/61034 for fire properties; local mining approvals required (e.g., MA/KA/Ex)

Key Features

High flexibility and fatigue endurance for trailing/reeling duty; tight bending radius

Flame‑retardant, oil‑, abrasion‑, and tear‑resistant rubber sheaths for harsh environments

Optional LSZH and low‑smoke performance for improved personnel safety

Shielded and intrinsically safe designs available for hazardous atmospheres (Ex i)

Robust insulation and screening to reduce electromagnetic interference and ensure stable operation

Suitable for damp environments and limited water ingress; options for enhanced waterproofing

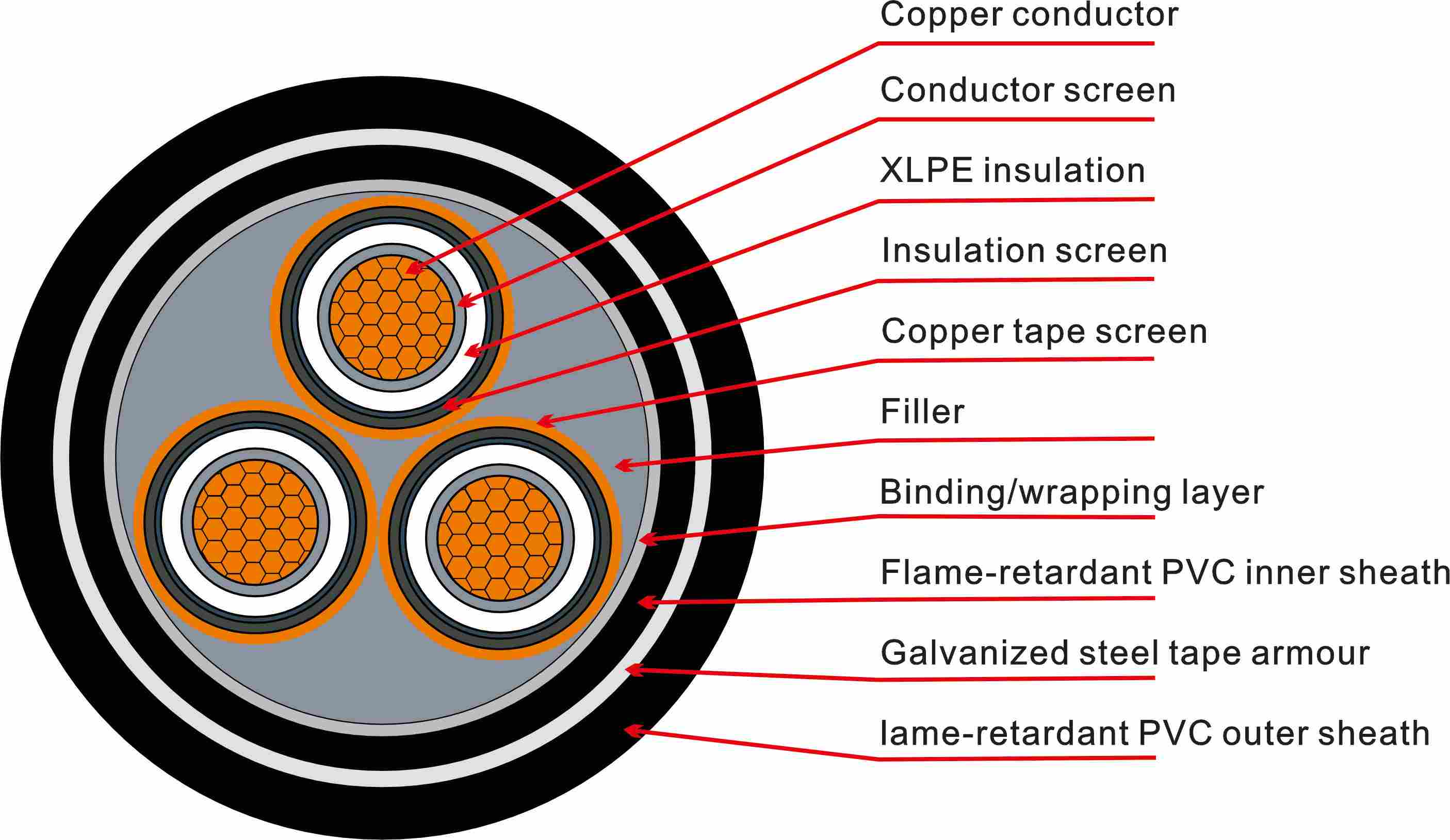

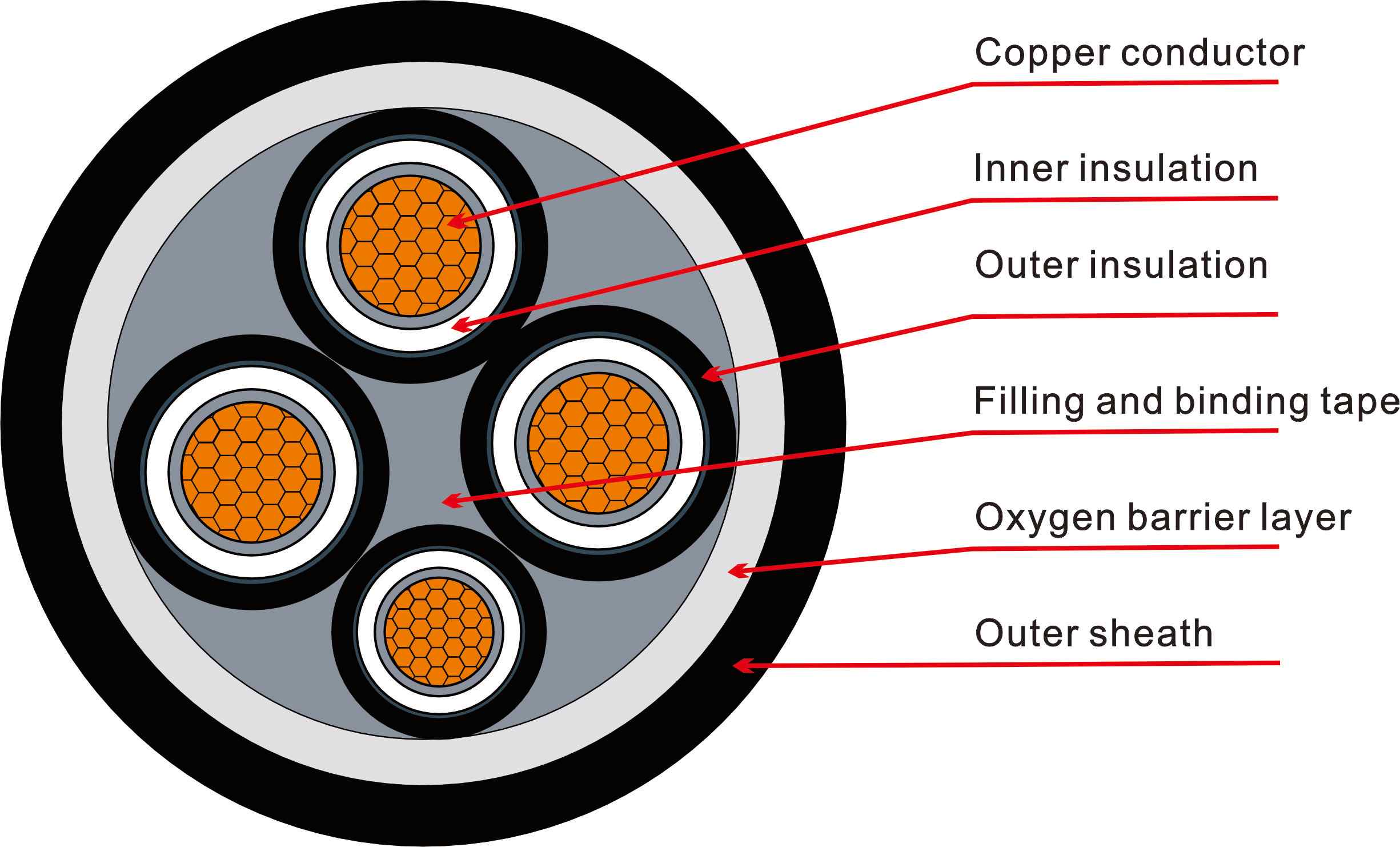

Layered from inside to outside

Factory photos

If you need technical support, please feel free to contact us.

![]()

Customization & Technical Support

• E-Mail: overseasales@tiankang.com

Sales Support:

• E-Mail: overseasales01@tiankanginternational.com

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2026 ANHUI TIANKANG (GROUP) SHARES CO.,LTD. All Rights Reserved. Network Supported

XML

Privacy Policy

Sitemap

Network Supported

XML

Privacy Policy

Sitemap

Email : overseasales@tiankang.com

Address : No.20 South Renhe Road,Tianchang,Anhui,P.R.C

Copyright @ 2026 ANHUI TIANKANG (GROUP) SHARES CO.,LTD. All Rights Reserved. Network Supported

Network Supported

Leave A Message