TianKang Group offers advanced aluminum alloy power cables engineered for reliable, cost-effective distribution in industrial and commercial projects. Using high-strength, corrosion-resistant alloy conductors with XLPE insulation, the cables deliver lower weight than copper while maintaining excellent electrical and mechanical performance. Options include MV/LV constructions, shielded or armoured designs, and PVC/PE/LSZH sheaths to meet diverse installation and fire-safety requirements. Products comply with IEC/GB standards and are supported by comprehensive technical services and customized solutions.

Overview

Aluminum Alloy (AAAC/Al-alloy) Power Cables are designed for reliable medium-to-low voltage distribution in industrial facilities, commercial buildings, and municipal infrastructure. By using high-strength, corrosion-resistant aluminum alloy conductors with optimized stranding, these cables offer lighter weight than copper, improved flexibility and fatigue resistance versus ordinary aluminum, and excellent cost-performance. XLPE insulation is typically used for superior electrical, thermal, and aging performance. Constructions are available with or without armour, with optional flame-retardant or LSZH sheaths, and with comprehensive shielding for MV applications.

Typical voltage ratings (power distribution):LV: 0.6/1 kV MV: 6/10 kV, 8.7/15 kV, 12/20 kV, 18/30 kV, 26/35 kV

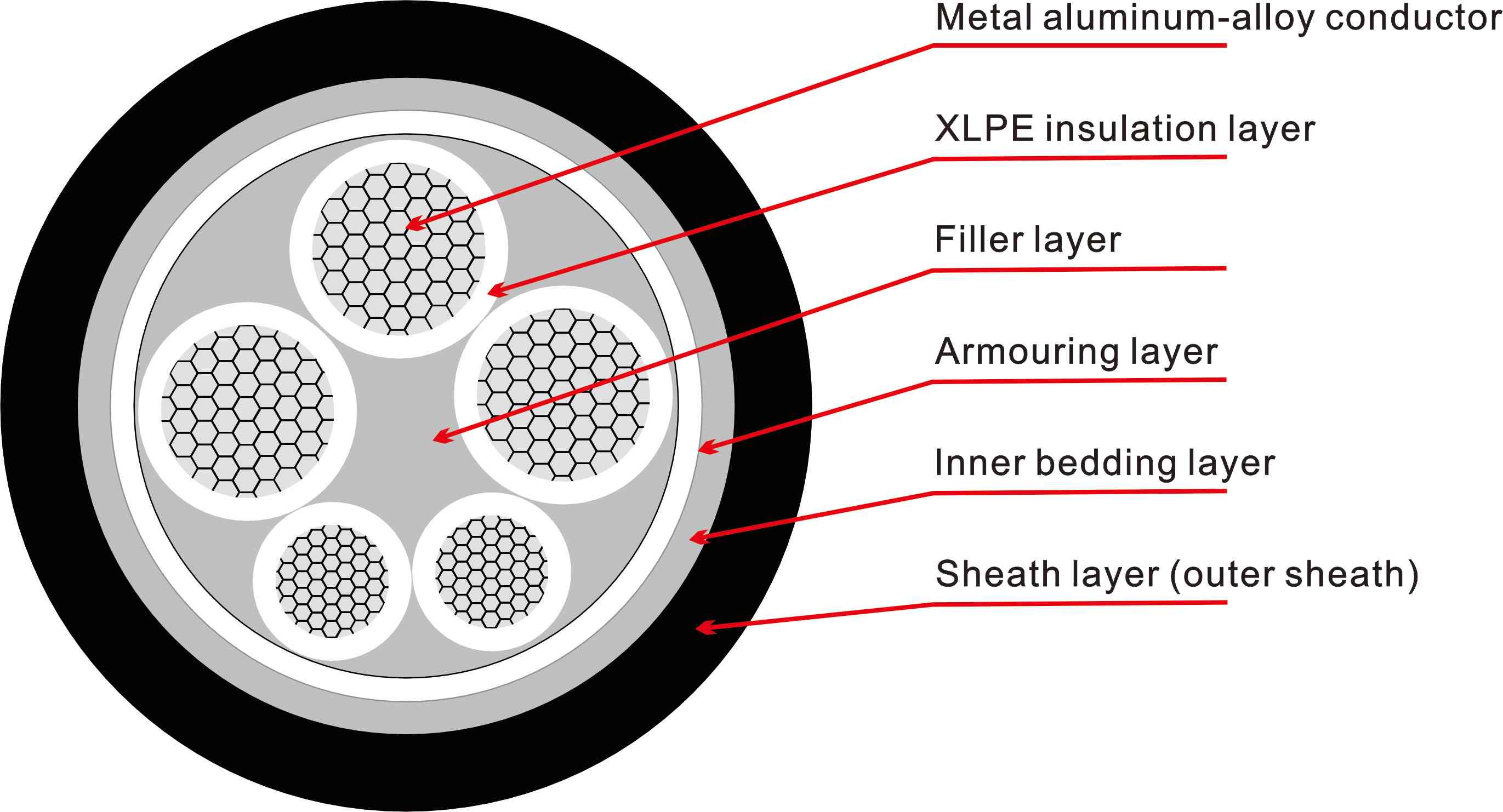

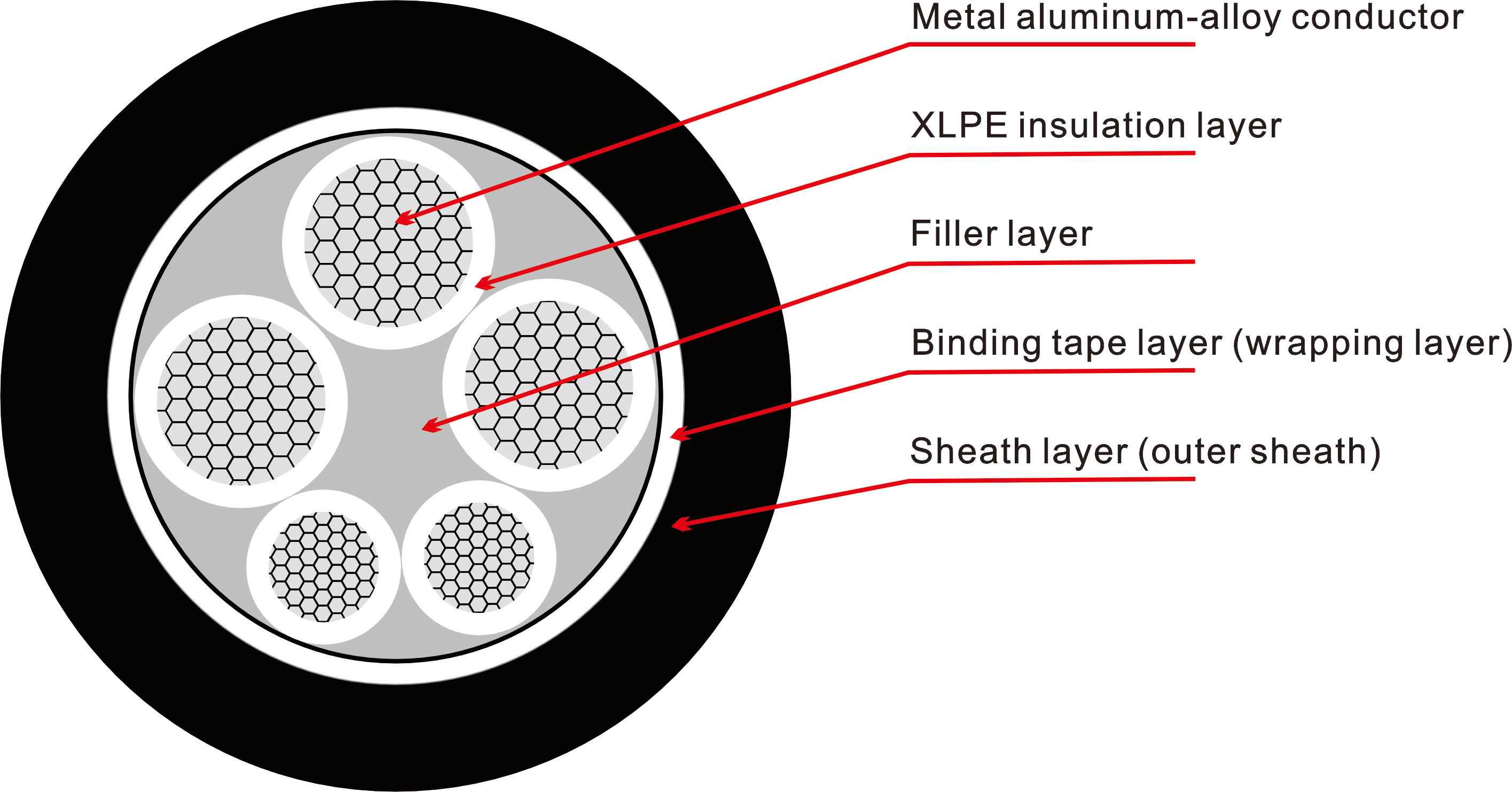

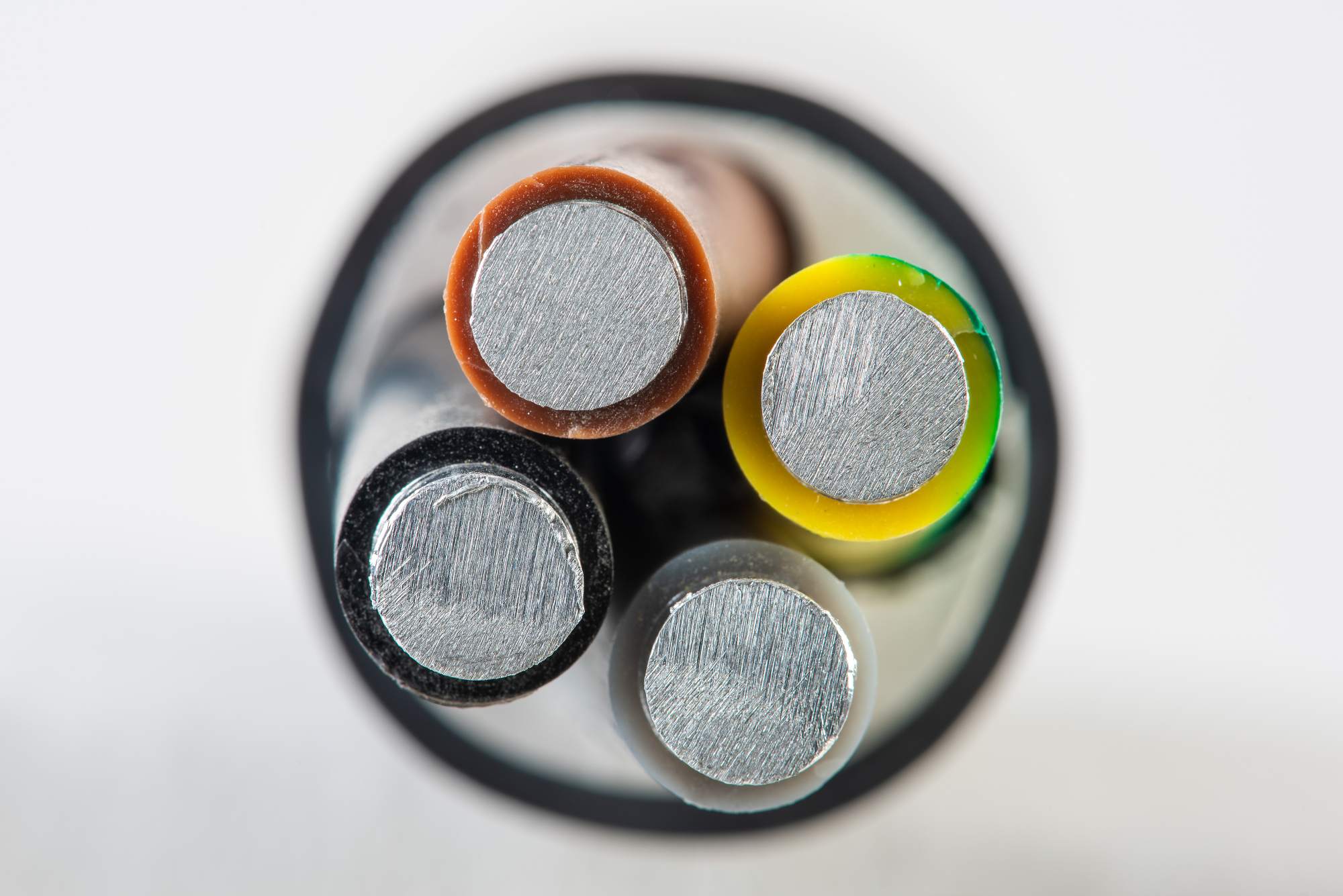

Conductors: Aluminum alloy (round/sector, compacted), class 2 or flexible class 5 on request

Insulation: XLPE as standard; PVC/EPR optional for specific applications

Shielding (MV types): Conductor/insulation semi-conductive screens + metallic screen (Cu wires/tape or Al tape)

Mechanical protection: Steel tape armour (STA) or steel wire armour (SWA); aluminum tape armour optional for corrosion control

Outer sheath: PVC, PE, or LSZH

Applications: Building feeders, industrial parks, utility distribution, municipal infrastructure, data centers, tunnels, trays, ducts, and direct burial

Standards: IEC 60502-1/-2, GB/T 12706.1/.2, ICEA/IEEE (as specified)

Key Features

High conductivity with reduced weight: 30–50% lighter than copper for easier installation and reduced support loads

Enhanced mechanical properties: Superior tensile strength, bending fatigue and creep resistance vs. plain aluminum

Excellent electrical reliability: XLPE insulation with high dielectric strength and low loss; continuous operating temperature up to 90°C

Robust shielding for MV: Semi-conductive screens and metallic screens to control electric field and partial discharge

Fire-safety options: Flame-retardant and LSZH sheaths available; CPR/GB fire classes on request

Broad installation methods: Suitable for trays, ducts, direct burial, tunnels, and trenches; good corrosion resistance

Layered from inside to outside

Factory photos

If you need technical support, please feel free to contact us.

![]()

Customization & Technical Support

• E-Mail: overseasales@tiankang.com

Sales Support:

• E-Mail: overseasales01@tiankanginternational.com

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2026 ANHUI TIANKANG (GROUP) SHARES CO.,LTD. All Rights Reserved. Network Supported

XML

Privacy Policy

Sitemap

Network Supported

XML

Privacy Policy

Sitemap

Email : overseasales@tiankang.com

Address : No.20 South Renhe Road,Tianchang,Anhui,P.R.C

Copyright @ 2026 ANHUI TIANKANG (GROUP) SHARES CO.,LTD. All Rights Reserved. Network Supported

Network Supported

Leave A Message