Thermocouples have become indispensable tools in modern industrial environments where accurate, stable, and real-time temperature measurement is essential. Among all thermocouple categories, Type K stands out as the most widely used and most versatile temperature sensor across industries. Its broad temperature range, durability, and cost-effectiveness make it a preferred option for engineers, maintenance teams, and equipment manufacturers.

1. What Is a Type K Thermocouple?

A Type K thermocouple is a temperature-sensing device composed of two dissimilar metals—Chromel (Ni-Cr) and Alumel (Ni-Al)—joined at one end to form a measuring junction. When this junction experiences temperature changes, it generates a voltage proportional to temperature, allowing accurate measurement using a meter or controller.

Type K belongs to the base-metal thermocouple group, known for affordability and simplicity.

2. Key Reasons Why Type K Is the Most Widely Used

Extremely Wide Temperature Range:

Type K thermocouples can measure from –200°C to +1260°C, covering everything from cryogenic cooling to high-heat furnaces.

This breadth makes it suitable for: Industrial ovens and kilns, Heat-treating systems, Boilers and exhaust gas monitoring, Aerospace and automotive testing, Few other sensors provide such flexibility at a reasonable cost.

Exceptional Durability and Oxidation Resistance:

The nickel-based alloys in Type K offer resistance against:Oxidation, Corrosion, High-temperature scaling, This makes Type K ideal for harsh industrial environments where exposure to moisture, chemicals, or combustion gases is common.

High Sensitivity and Fast Response:

Type K generates approximately 41 µV/°C, providing: Fast response to temperature changes, Stable readings under continuous operation, Reliable performance in dynamic processes, This is critical in applications such as automated process control.

Cost-Effective Compared to Noble-Metal Thermocouples:

Compared with Type R, S, or B thermocouples (which contain platinum), Type K offers: Lower cost, Lower maintenance, Greater availability,For industries requiring hundreds or thousands of sensors, cost efficiency makes Type K the practical choice.

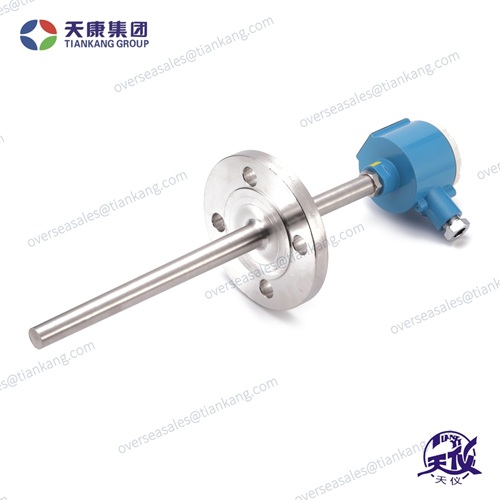

Availability in Many Configurations:

Type K is available in countless forms: Probe-style thermocouples, Surface sensors, Mineral-insulated sheathed cables, High-temperature ceramic-sheathed designs, Bolt-on, ring, or magnetic contact types, This versatility allows engineers to integrate the same sensor type into many different systems.

3. Limitations of Type K Thermocouples

Susceptibility to Drift at Very High Temperatures: Prolonged exposure above 1000°C may cause accuracy drift due to metallurgical changes.

Sensitive to Magnetic Fields: As a nickel-based sensor, it is more affected by magnetic interference than some other thermocouples.

Not Suitable for Vacuum or Reducing Atmospheres: Type K performs best in oxidizing environments; inert or reducing atmospheres may cause degradation.

For extreme environments, Types N, R, or S may perform better.

Because of its durability, range, and cost advantages, Type K is used in nearly all major industries:

Manufacturing: Heat treatment furnaces, Plastic extrusion machines, Injection molding machines, Metal casting and forging

Energy & Power Plants: Boilers, Turbines, Exhaust gas monitoring, Fuel combustion systems

Chemical & Petrochemical: Reactors, Distillation columns, Cryogenic systems, Process control pipelines

Food & Pharmaceutical: Sterilization, Steam systems, Industrial ovens, Continuous process monitoring

Automotive & Aerospace: Engine testing, Battery pack thermal management, Exhaust emissions measurement

Type K’s flexibility makes it suitable for both fixed installations and portable testing devices.

Thermocouple Type K remains the most widely used temperature sensor across industries due to its proven reliability, affordability, and ability to function in extreme temperature conditions. Whether used in manufacturing, energy production, chemical processing, or R&D, Type K thermocouples deliver stable performance essential for efficient and safe operation.

If you need help customizing Type K thermocouples or selecting the right configuration for your application, feel free to ask Tiankang Hongji.

Email : overseasales@tiankang.com

Email : sales03@tiankanginternational.com

Email : sales07@tiankanginternational.com

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2026 ANHUI TIANKANG (GROUP) SHARES CO.,LTD. All Rights Reserved. Network Supported

XML

Privacy Policy

Sitemap

Network Supported

XML

Privacy Policy

Sitemap

Email : overseasales@tiankang.com

Address : No.20 South Renhe Road,Tianchang,Anhui,P.R.C

Copyright @ 2026 ANHUI TIANKANG (GROUP) SHARES CO.,LTD. All Rights Reserved. Network Supported

Network Supported

Leave A Message